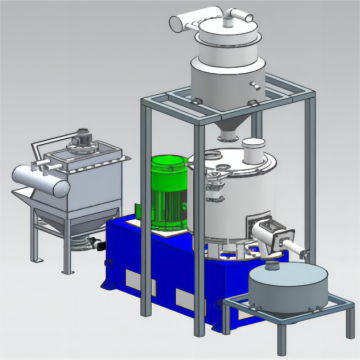

Multi-functional Jet Mill for powders

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

Your message must be between 20 to 2000 characters

Contact NowDetailed Introduction

I. Introduction to the Multi-functional Grinder

The SCWN multi-functional grinder, also known as a stainless steel grinder, high-efficiency grinder, food grinder, hammer mill, multi-functional grinder, chemical grinder, and pharmaceutical grinder, is developed and produced based on similar products from Japan, Germany, and the United States.

II. Detailed Description of the Multi-functional Grinder

The multi-functional grinder features a simple and sturdy structure, smooth operation, easy cleaning, and excellent grinding effects. The crushed material can be directly discharged from the grinding chamber of the main unit, and the particle size can be obtained by replacing different aperture screens. The multi-functional grinder is made entirely of stainless steel. The inner wall of the grinder's casing is machined to achieve a smooth surface, eliminating the rough interior and powder accumulation issues of previous models, making it more compliant with national standards for pharmaceutical, food, and chemical production, meeting GMP requirements. Generally, the fineness of materials can reach 100-280 mesh.

III. Application Scope of the Multi-functional Grinder

The multi-functional grinder is the most commonly used practical model in pharmaceutical factories, food factories, chemical factories, hospital pharmacies, clinics, outpatient departments, research institutes, health product factories, building material factories, feed factories, and other units.

IV. Usage of the Multi-functional Grinder

-

The multi-functional grinder is packaged as a whole unit. After unpacking, move it to an appropriate location, place it stably, connect the power supply, and it can be tested.

-

Before use, check if there is any looseness or other abnormalities in the mechanical transmission parts. The machine's operating direction should be consistent with the direction indicated by the arrow.

-

Perform a no-load test for 1-2 minutes before use. After observing no abnormalities, start feeding. Gradually increase the material flow rate while observing the motor's current consumption and operation. Once the feeding and current balance are stable, fix the lower feed gate and proceed with the work.

-

If the material is too damp or sticky, affecting the powder output, the material should be dried or a coarser screen should be replaced. Replacing the screen only requires opening the front cover.

-

When installing the front cover, ensure that the handwheels on both sides are tightened evenly to ensure a tight seal between the front cover and the machine casing. Before stopping, stop feeding first and let the machine run for 5-10 minutes to reduce residual material.

Related Keywords