crushing and grading equipment for ternary materials

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

Your message must be between 20 to 2000 characters

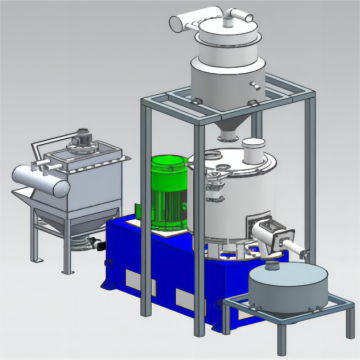

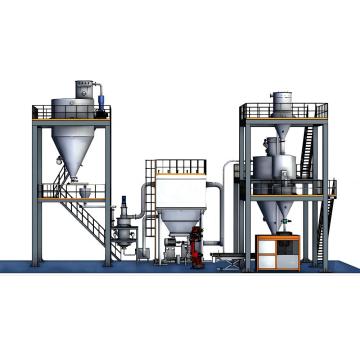

Contact NowSpecialized crushing and grading equipment for ternary materials consists primarily of three major product categories with over a dozen series offered by our company. Customized for varying production requirements and applications, our equipment offers high yield rates, uniform particle size distribution, and excellent particle morphology.

Application Areas:

Battery cathode and anode materials: typical materials include lithium cobalt oxide, lithium manganate, lithium iron phosphate, lithium nickel cobalt oxide, lithium nickel cobalt manganese oxide, lithium iron phosphate, manganese dioxide, lithium carbonate, cobalt oxide, ferrous oxalate, lithium hydroxide, graphite, coke powder, carbon microspheres, pitch, lithium titanate, silicon, silicon monoxide, iron phosphate, etc.

Main Technical Parameters:

| Equipment Model | Air Consumption (m³/min) | Pressure (Mpa) | Feed Particle Size (mm) | Discharge Particle Size (um) | Production Capacity (kg/h) | Installed Power (kw) | Remarks |

| SCWN-Q100 | 3 | 0.8-1.0 | ≤1 | 1-45 | 1-10 | ≤28 | Laboratory Type |

| SCWN-Q200 | 6 | 0.8-1.0 | ≤2 | 1-45 | 10-50 | ≤70 | |

| SCWN-Q300 | 10 | 0.8-1.0 | ≤2 | 1-45 | 30-100 | ≤95 | |

| SCWN-Q400 | 20 | 0.8-1.0 | ≤2 | 1-45 | 50-300 | ≤160 | Industrial Type |

| SCWN-Q600 | 40 | 0.8-1.0 | ≤2 | 1-45 | 100-500 | ≤320 |

Equipment Features:

-

The jet mill possesses shaping capabilities, resulting in excellent particle morphology and spherical (potato-shaped) particles.

-

Narrow particle size distribution and high tapped density of the finished product.

-

Wear-resistant lining inside the equipment ensures high purity of the finished product and minimal wear on the equipment.

-

Stable operation with no differences or changes after prolonged continuous operation.

-

Fully enclosed negative pressure operation, automated control, low noise, and no dust pollution.

Related Keywords