Ribbon Mixer ,Ribbon Blender,Blender Mixer

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

Your message must be between 20 to 2000 characters

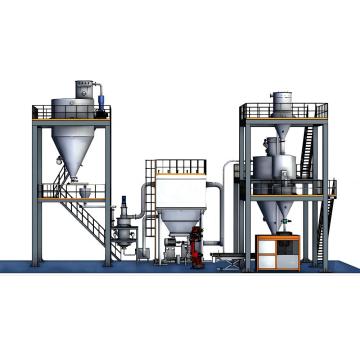

Contact NowScope of Application:

The SCWN horizontal ribbon mixer is applicable for the mixing of solid-solid (powder to powder) and solid-slurry (powder to slurry) materials in industries such as pesticides, veterinary drugs, food, chemicals, biotechnology, aquaculture, ceramics, refractory materials, plastics, and compound fertilizers. It is particularly suitable for mixing viscous materials.

Performance Characteristics:

-

The SCWN horizontal ribbon mixer is not affected by particle size or density under feasible operating conditions.

-

It achieves good mixing results for viscous materials.

-

The smooth mixing process reduces damage to fragile materials, and the addition of a flying knife structure also serves as a crushing function.

-

The horizontal structure and low body height facilitate installation.

-

The oppositely rotating screw blades installed on the same horizontal axis create a low-power and highly efficient mixing environment.

Working Principle:

-

The SCWN horizontal ribbon mixer utilizes inner and outer spiral blades installed on the mixing shaft to drive the material within the mixing barrel, enabling the agitator to flip the material within a wide range inside the barrel.

-

Structurally, the spirals are designed as inner and outer, left and right, mutually opposite spirals. When the agitator works, the inner spiral drives the material near the shaft to rotate around the shaft center, pushing axially from the inside to both sides. The outer spiral drives the material near the barrel wall to rotate around the shaft center, pushing axially from both sides to the inside. This results in the convection circulation, shear mixing, and rapid and uniform mixing of the material within a short period of time.

Type Total Volume(m³) Production Capacity(kg/1 time) Mixing Time (min) Motor Power (kw) Stirring Speed (r/min) Weight (kg) SCWN-100 0.1 40 8-20 2.2 58 400 SCWN-300 0.3 120 8-20 5 53 800 SCWN-500 0.5 200 8-20 5.5 49 1000 SCWN-1000 1 400 8-20 7.5 42 1450 SCWN-1500 1.5 600 8-20 11 42 1950 SCWN-2000 2 800 8-20 15 42 2650 SCWN-3000 3 1200 8-20 18.5 37 3300 SCWN-4000 4 1600 8-20 22 37 3620 SCWN-5000 5 2000 8-20 30 31 4620 SCWN-6000 6 2400 8-20 37 31 5400 SCWN-8000 8 3200 8-20 45 27 6880 SCWN-10000 10 4000 8-20 55 27 7900

Related Keywords