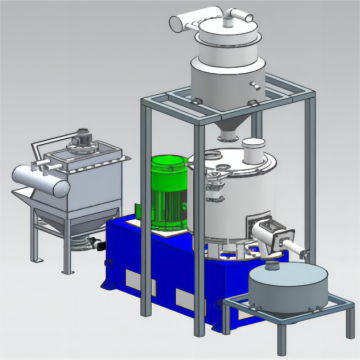

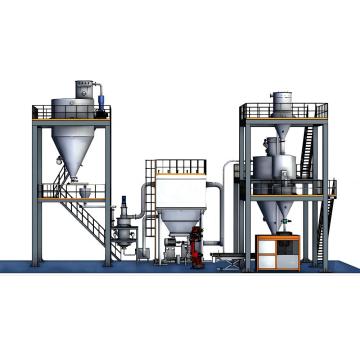

Especial Nano Powder Classification Machine

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|

Product Description

Product Description

Working principle:

After the material enters the classifier through the feeding port of the feeding mechanism, it is evenly distributed by the distribution plate on the vertical classification wheel and thrown into the retaining ring, falling into the classification area.

Graded air enters the spiral shaped wind chamber and flows into the grading wheel in a centripetal direction through the guide plate blades. Fine powder that meets the particle size requirements is separated under the gravity of the grading area.

Fine powder flows at high speed together with graded air and enters the fine powder capture system, then separates from the graded air. The coarse powder falls into the lower part of the classifier and is discharged by an electric discharge valve with an air seal.

Features:

1. Wide classification range: This machine can classify any organic or inorganic material, with a particle size of D97=3-74um. It can classify spherical, flake, and fiber particles, as well as separate materials with significant differences in specific gravity.

2. High classification accuracy: With a complete and stable classification flow field and reliable sealing, materials can be accurately classified. D97/D50, D75/D25=1.1~1.5.

3. High classification efficiency: The strong eddy current field and the setting of the fine powder purification device can efficiently classify fine powder, with a Newtonian efficiency of 70-95.

4. The high-speed and complete external classification flow field greatly eliminates the wear of classification equipment. Equipped with a strong dispersion device, it can effectively disperse and grade agglomerated powders.

5. Flammable, explosive, and oxidizable materials can be classified in a closed circuit using inert gas as a medium, and inert gas can be recycled for use. The multi-level grading series can be equipped with 1-5 levels of airflow classifiers, which divide materials into several particle size segments to produce products with narrow particle size distribution requirements.

After the material enters the classifier through the feeding port of the feeding mechanism, it is evenly distributed by the distribution plate on the vertical classification wheel and thrown into the retaining ring, falling into the classification area.

Graded air enters the spiral shaped wind chamber and flows into the grading wheel in a centripetal direction through the guide plate blades. Fine powder that meets the particle size requirements is separated under the gravity of the grading area.

Fine powder flows at high speed together with graded air and enters the fine powder capture system, then separates from the graded air. The coarse powder falls into the lower part of the classifier and is discharged by an electric discharge valve with an air seal.

Features:

1. Wide classification range: This machine can classify any organic or inorganic material, with a particle size of D97=3-74um. It can classify spherical, flake, and fiber particles, as well as separate materials with significant differences in specific gravity.

2. High classification accuracy: With a complete and stable classification flow field and reliable sealing, materials can be accurately classified. D97/D50, D75/D25=1.1~1.5.

3. High classification efficiency: The strong eddy current field and the setting of the fine powder purification device can efficiently classify fine powder, with a Newtonian efficiency of 70-95.

4. The high-speed and complete external classification flow field greatly eliminates the wear of classification equipment. Equipped with a strong dispersion device, it can effectively disperse and grade agglomerated powders.

5. Flammable, explosive, and oxidizable materials can be classified in a closed circuit using inert gas as a medium, and inert gas can be recycled for use. The multi-level grading series can be equipped with 1-5 levels of airflow classifiers, which divide materials into several particle size segments to produce products with narrow particle size distribution requirements.

6. Fully enclosed negative pressure operation, without dust pollution.

Related Keywords

Related Keywords