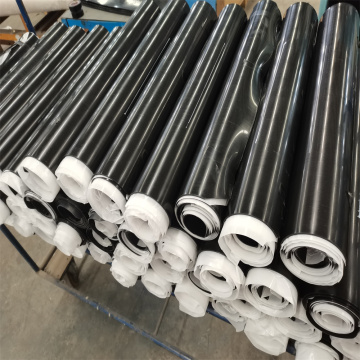

Heat shrinkable wrapid sleeves

-

$30.00≥500 Others

- Min. Order:

- 500 Others

- Min. Order:

- 500 Others

- Transportation:

- Ocean, Land

- Port:

- Shanghai , Qingdao , Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 500 PCS/Day |

| Supply Ability: | 5000 rolls/Month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF |

| Certificate: | ISO |

| HS Code: | 3920 |

| Transportation: | Ocean,Land |

| Port: | Shanghai ,Qingdao ,Shenzhen |

Heat shrinkable wrapid sleeves for onshore oil and gas pipelines

Heat shrink wrapid Sleeves provide great corrosion protection, Superior resistance to Cathodic Disbondment and excellent durability against abrasion and chemical attack. The result is effective, good performance of sealing, wide application, easy to operate and preheating temperature low (50 ℃) ,long term protection against corrosion.

wrapid sleeves in bulk roll is also two-piece protective with separate closure

Inner layer is two-components epoxy primer which coated on steel pipe ; Intermediate level is special hot melt adhesive ;

Outer layer is modified radiation crossing linking polyethylene backing.

Features & Benefits

Cross-linked backing provides superior abrasion, mechanical and chemical attack resistance.

High performance adhesive provides excellent resistance to Cathodic Disbondment to ensure long-term corrosion protection

Just-in-time customized lengths allow bulk rolls to be field cut top protect any pipe size

Open sleeve configuration allows the product to be applied after the pipeline has been welded and cleaned.

A broad range of operating temperature specific and soil stress resistant adhesives for project specific conditions

Specification( mm )

Wrapid sleeves 2170 /550/ Ø 610

Wrapid --Heat shrinkable wraparound sleeves

2170------ Roll length

550----- -Roll Width (as supplied)

Ø 610-----Joint or pipeline Diameter

Item

Performance Parameter

re-producable data

UNITS

TEST

METHODS

1

Backing thickness (as supplied) , min

1.0

mm

ASTM D 1000

2

Adhesive thickness (as supplied), min

1.0/1.5

mm

ASTM D 1000

3

Total thickness (as installed) , min

2.0/2.5

mm

ASTM D 1000

4

Hardness at 23 0C

50

Shore D

ASTM D-2240

5

Ring and ball softening point of adhesive,

100

0C

ASTM E 28

6

Impact resistance at 23 0C

15

J(inch-lb)

EN 12068

7

Peel strength to pipe surface and

factory coating - at 23 0C

at 50 0C

1.5

0.3

N/mm

N/mm

EN 12068

Annex C

8

Peel strength @10mm/min to pipe surface and

To factory coating after 28 days hot water soak test at 50 0C

2.5

N/mm

ISO 21809-3

Annex I

9

Cathodic disbondment resistance

- at 23 0C

at 50 0C

8

15

N/mm

N/mm

EN 12068

Annex k

10

Lap shear strength to pipe surface at 500C

0.05

N/mm2

EN 12068

11

Specific electrical insulation resistance,

R s100, min

1010

Ω. m2

EN 12068

Annex J

12

Ultimate elongation ,min

400

%

ASTM D638

13

Heat aging 21 days at 150 0C -elongation

200

%

ASTM D638

15

Heat shork hours at 2250C

No cracking,flow or dripping

Visual

ASTM D2671

17

Soil stress creepyResistance24 h at 50 0C

2.5

mm

TP206

18

Ultraviolet irradation resistance

Ratio of elongation at break

1.25≥EX/E 0≥0.75

--

EN 12068

Annex F

Sichuan Forever main products has heat Shrinkable Sleeves, Pipe Repair Material,Liquid Epoxy Coatings,Visco-Elastic Coating Materials,Cold-Applied Polymeric Tape and other Wrapping materials application tooling.

Related Keywords