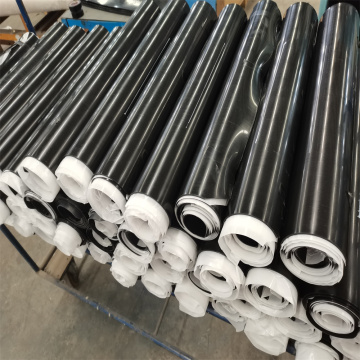

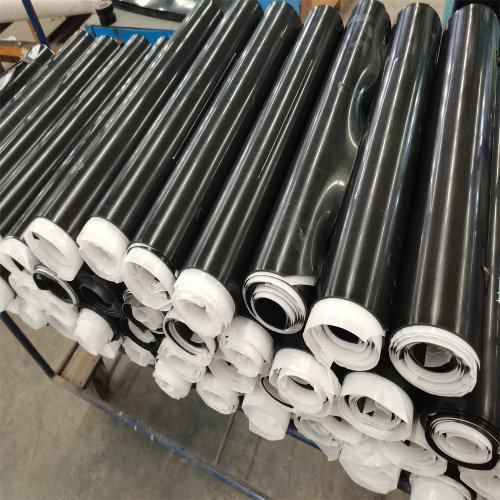

Heat Shrinkable Sleeve for 3LPE Coating Pipe

-

$1.00≥100 Set/Sets

- Min. Order:

- 100 Set/Sets

- Min. Order:

- 100 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

- Port:

- Shanghai, Shenzhen, Qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 2000 Sets per day |

| Supply Ability: | 5000 sets per day |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP,DDU,Express Delivery |

| Certificate: | ISO9001,ISO 14001 |

| HS Code: | 39201090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai,Shenzhen,Qingdao |

Heat Shrinkable Sleeve for 3 Layer PE Coating Pipe provide mechanical protection to the epoxy layer and

seal onto the epoxy layer and the adjacent line coating.

The first layer of the joint coating system is a 100 % solids two component

epoxy of a minimum dry-film thickness of 150 microns when applied on the steel surface. The epoxy layer is the primary anti-corrosion barrier and

capable of corrosion protecting the steel surface on a standalone basis

Backing: > 1.0 mm

Adhesive: > 1.0 mm

Total sleeve (Backing + Adhesive): > 2.0 mm

To prevent damage to the adjacent 3LPE line coating, the pre-heat of the weld area prior to epoxy application shall not exceed 80℃. After application of epoxy to joint area, the shrink sleeve shall be shrunk over the epoxied surface while the epoxy is still in a gel state and shall not require post curing of the epoxy layer prior to sleeve shrinking. This is to prevent contamination of the epoxy surface caused by direct flame.

Sichuan Forever main products has heat Shrinkable Sleeves, Pipe Repair Material,Liquid Epoxy Coatings,Visco-Elastic Coating Materials,Cold-Applied Polymeric Tape and other Wrapping materials application tooling.

How to choose the width of HSS ?

The sleeves on the weld joint shall be wide enough so as to overlap onto the

mainline coating by a minimum of 50 mm on each side of the weld joint once

installed. The installed sleeve width shall be considered as the edge-to-edge width of the backing of the sleeve once fully shrunk down.

The sleeves on field bends may be wider and shall overlap onto each other by a minimum of 50 mm once installed.

Performance requirements for the physical, chemical and electrical properties as following :

|

Performance Parameter |

Test method |

Required Result |

|

Epoxy |

|

|

|

Dry Film Thickness on steel |

|

≥150 micron |

|

Pull off adhesion strength to steel at 23°C |

ASTM D4541 |

≥15 MPa |

|

Shrink Sleeve Backing |

|

|

|

Sleeve Backing thickness |

- |

≥ 1.0 mm |

|

Density |

ASTM D792 |

≥0.95 gm/cc |

|

Hardness of backing |

ASTM D2240 |

≥55 Shore D |

|

Shrink Sleeve Adhesive |

|

|

|

Sleeve adhesive thickness |

- |

≥ 1.0mm |

|

Ring and Ball Softening Point of adhesive |

ASTM E-28 |

≥120°C |

|

Lap Shear Strength of adhesive |

ASTM D-1002 |

> 0.35 MPa (50 psi) @ 80°C |

|

Peel Strength of installed sleeve at 80°C (pull rate of 10 mm/min) to pipe surface (steel) to factory coating (PE coating) |

EN 12068 |

> 2 N/cm > 2 N/cm |

|

Penetration resistance @ 80°C for 24 hours |

ASTM G-17 |

No holiday at 10 kV |

|

Impact Resistance at 23°C |

EN 12068 Class C |

Pass |

|

Ultraviolet resistance |

EN 12068 – Annex F |

Pass |

|

Moisture Vapor Transmission of sleeve at 38°C, 90 % RH |

ASTM E-398 |

<0.08 gm/ 24 hrs/100 sq.in |

|

Cathodic disbondment of installed sleeve at 80°C after 30 days |

ASTM G-42 |

< 15 mm |

|

Soil Stress Creep Resistance of installed sleeve at 80°C |

TP-206 |

< 0.1 inch after 24 hours |

|

Hot Water Immersion resistance of installed sleeve at 80°C for 120 days |

ASTM D-870 |

No blisters or determination. No water under sleeves. |

|

Holidays Detection |

|

Pass at 5kV/mm + 5kV |

Related Keywords