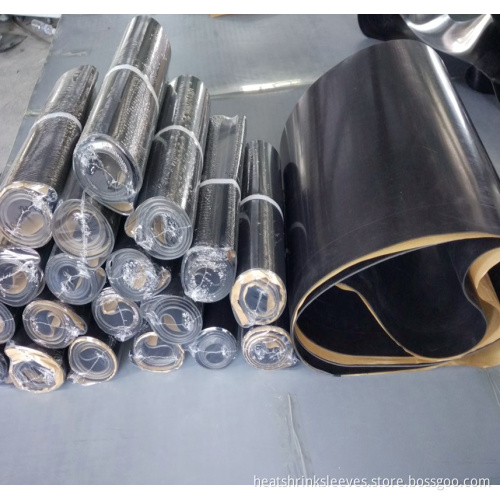

Htpl 80 Heat Shrink Sleeves With Closure Patch

-

$50.00≥10 Roll

- Min. Order:

- 10 Roll

- Min. Order:

- 10 Roll

- Transportation:

- Ocean, Land

- Port:

- Qingdao , Shenzhen, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 5000 rolls/Month |

| Supply Ability: | 5000 rolls/Month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CIF,EXW |

| Certificate: | ISO |

| HS Code: | 392190 |

| Transportation: | Ocean,Land |

| Port: | Qingdao ,Shenzhen, Shanghai |

3LPE 80C Heat Shrink Sleeves

3LPE 80C Heat Shrink Sleeves is developed by Forever on the basis of the original product. It is the first of the same kind in China. Currently, the product is well above the domestic anticorrosive professional standards and reaches the standard requirement of EN12068 ,ISO21809-3 and ASTM as well.

HT80 is a wraparound sleeve with a separate closure patch,Cross-linked backing provides superior abrasion, mechanical and chemical

attack resistance.High temperature adhesive provides excellent resistance to Cathodic Disbondment to ensure long-term corrosion

protection,Just-in-time customized lengths allow bulk rolls to be field cut top protect any pipe size, Open sleeve configuration allows the

product to be applied after the pipeline has been welded and cleaned.

HT80 is superior performance heat shrinkable products designed for corrosion protection on field applied girth-weld joints of buried and exposed steel pipelines operating up to 80°C

Heat Shrinkable Sleeves covered 3LPE Heat Shrink Sleeves,2PE Heat Shrink Tape,3LPP Wrap Around Sleeve

HDD Heat Shrink Wrap Sleeves,Shrinkable Tape Closure Patch

|

| Layer 1:The inner layer is two-components epoxy primer which coated on steel pipe; |

| Layer 2:Intermediate level is special hot melt adhesive ; |

|

Layer 3:Outer layer is modified radiation crossing linking polyethylene backing. |

|

No. |

Property |

Unit |

Test Result |

Test Method |

|

|

PE Backing Layer |

|||||

|

1 |

PE Backing Layer Thickness, at 23 ℃ |

mm |

0.8/1.2/1.5 |

ASTM D 1000- 17 |

|

|

2 |

Tensile Strength (50mm/min), at 23 ℃ |

PSI |

3200 |

ASTM D638-22 |

|

|

3 |

Elongation at Break (50mm/min), at 23 ℃ |

% |

550 |

ASTM D638-22 |

|

|

4 |

Dielectric Strength, at 23 ℃ |

KV/mm |

35 |

ASTM D 149-20 |

|

|

6 |

Linear Thermal Shrinkage |

% |

35 |

ASTM D2732- 14 |

|

|

Adhesive Layer |

|||||

|

1 |

Adhesive Layer Thickness, at 23 ℃ |

mm |

1.00/1.30 |

ASTM D 1000- 17 |

|

|

2 |

Ring and Ball Softening Point |

℃ |

120 |

ASTM E28- 18 |

|

|

3 |

Adhesive Lap Joint Shear Strength |

PSI |

600 |

ASTM D 1002- 10 |

|

|

Heat Shrinkable Sleeves Coatings Physical Properties |

|||||

|

1 |

Impact Resistance, at 23℃ |

|

≥15 |

19.6 |

EN 12068:1999 |

|

2 |

Shore Hardness, at 23℃ |

D |

≥50 |

55 |

ASTM D2240- 15 |

|

3 |

Peel strength (10mm/min), to PE ° |

N/cm |

≥10.0 |

110 |

DIN 30672-2000 |

|

4 |

Cathodic Disbondment 30d, at 60℃ |

mm |

≤25 |

12 |

ASTM G42- 11 |

Related Keywords