Radiation Cross Linked Heat Shrinkable Sleeves

- Min. Order:

- 500 Set/Sets

- Min. Order:

- 500 Set/Sets

- Transportation:

- Ocean, Land, Air

- Port:

- Qingdao , Shenzhen, Shanghai

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 50000 sets/Month |

| Supply Ability: | 50000 set/Month |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Certificate: | ISO |

| HS Code: | 392190 |

| Transportation: | Ocean,Land,Air |

| Port: | Qingdao ,Shenzhen,Shanghai |

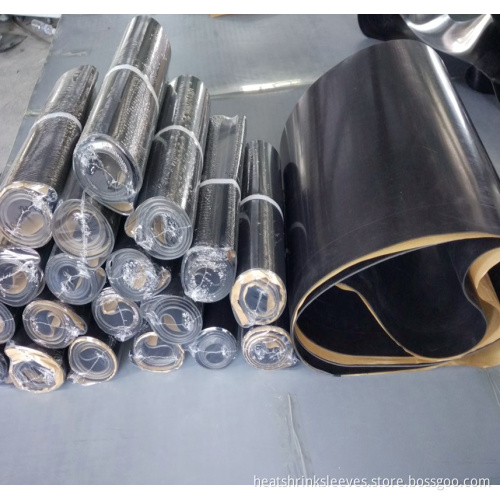

Cross-linked Heat shrinkable sleeves

Heat shrinkable sleeves ,Two-piece, with separate closures designed for the corrosion protection. Heat shrinkable sleeves is superior performance heat shrinkable products designed for corrosion protection on field applied girth-weld joints of buried and exposed steel pipelines operating up to 80°C (176°F).

Heat shrinkable sleeves has three layers, The inner layer is two-components epoxy primer which coated on steel pipe ; Intermediate level is special hot melt adhesive ; Outer layer is modified radiation crossing linking polyethylene backing.

Heat shrink sleeves Features & Benefits:

- HSS is a wraparound sleeve with a separate closure

- Cross-linked backing provides superior.abrasion, mechanical and chemical attack resistance.

- High performance adhesive provides excellent resistance to Cathodic Disbondment to ensure long-term corrosion protection

- Just-in-time customized lengths allow bulk rolls to be field cut to protect any pipe size

- Open sleeve configuration allows the product to be applied after the pipeline has been welded and cleaned.

Sichuan Forever main products has heat Shrinkable Sleeves, Pipe Repair Material,Liquid Epoxy Coatings,Visco-Elastic Coating Materials,Cold-Applied Polymeric Tape and other Wrapping materials application tooling.

Model: HSS Ø 426mm/ 500mm/ 2.5mm

HSS -------Heat shrinkable sleeves

500mm -----Width of sleeves (as supplied)q

Ø 426mm ----Joint or pipeline Diameter

Note: The Size can be ordered according to customers’demands

No.

Property

Unit

Test Result

Test Method

PE Backing Layer

1

PE Backing Layer Thickness, at 23 ℃

mm

0.8/1.2/1.5

ASTM D 1000- 17

2

Tensile Strength (50mm/min), at 23 ℃

PSI

3200

ASTM D638-22

3

Elongation at Break (50mm/min), at 23 ℃

%

550

ASTM D638-22

4

Dielectric Strength, at 23 ℃

KV/mm

35

ASTM D 149-20

6

Linear Thermal Shrinkage

%

35

ASTM D2732- 14

Adhesive Layer

1

Adhesive Layer Thickness, at 23 ℃

mm

1.00/1.30

ASTM D 1000- 17

2

Ring and Ball Softening Point

℃

120

ASTM E28- 18

3

Adhesive Lap Joint Shear Strength

PSI

600

ASTM D 1002- 10

Heat Shrinkable Sleeves Coatings Physical Properties

1

Impact Resistance, at 23℃

≥15

19.6

EN 12068:1999

2

Shore Hardness, at 23℃

D

≥50

55

ASTM D2240- 15

3

Peel strength (10mm/min), to PE °

N/cm

≥10.0

110

DIN 30672-2000

4

Cathodic Disbondment 30d, at 60℃

mm

≤25

12

ASTM G42- 11

![]() m

m

Related Keywords