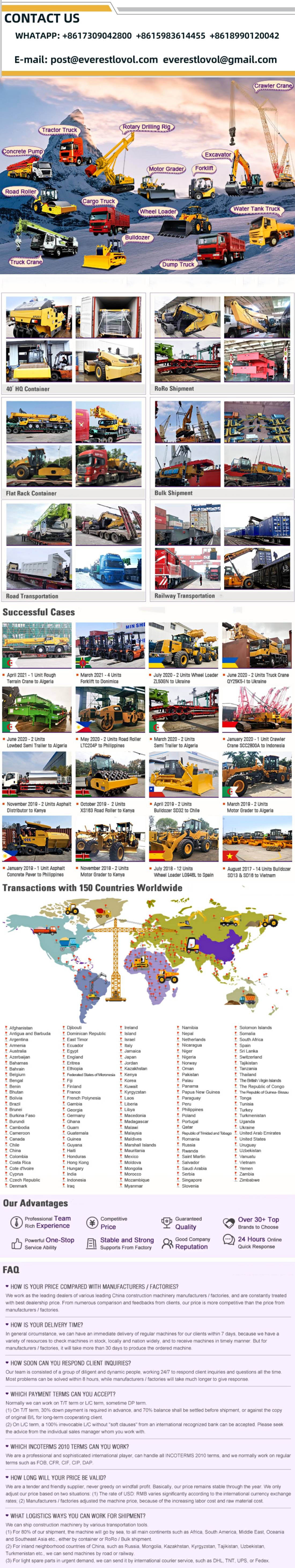

33ton Crawler Excavator FR330D with Spare Parts

- Transportation:

- Ocean, Land

- Port:

- qingdao

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | L/C,T/T,Western Union,Others |

| Incoterm: | FOB,CFR,CIF |

| Transportation: | Ocean,Land |

| Port: | qingdao |

33ton Crawler Excavator FR330D with Spare Parts

Medium excavator equipped with original ISUZU engine imported from Japan which can provide strong power when working with low fuel consumption, the fuel efficiency is improved dramatically.

Medium wheeled excavator YANMAR engine imported from Japan which can provide strong power with low fuel consumption,excavator machine the fuel efficiency has been improved dramatically.

TECHNICAL SPECIFICATIONS

PRODUCT PARAMETERS

Item

Unit

Parameter

Rated Power

kW/rpm

190.5/2000

Bucket Capacity

m³

1.5

Operating Weight

kg

33600

Engine Model

-

ISUZU AA-6HK1XQP

Number of Cylinders

-

6

Max. Torque/Speed

N·m/rpm

872.8/1700

Displacement

L

7.79

Bucket Digging Force

kN

223

Arm Digging Force

kN

170

Max. Traction Force

kN

290

Max. Walking Speed

km/h

5.5

Min. Walking Speed

km/h

3.3

Rotary Speed

r/min

9.2

Gradeability

°

35

Ground Pressure

KPa

67

Max. Main Pump Flow

L/min

560

Main Safety Valve Pressure

MPa

34.3

Fuel Tank

L

630

Hydraulic Tank

L

340

Engine Oil

L

38

PERFORMANCE

With sufficient power matched with large flow hydraulic system, and equipped with electronic negative flow control technology, it can fully undertake the difficult tasks of mining work.

— High power engine

Equipped with original YANMAR engine imported from Japan which can provide strong power with low fuel consumption, the fuel efficiency has been improved dramatically.Originally imported ISUZU engine with rated power 190.5 kW, comply with China stage II emission standard of off - road mobile machinery.

— Electronically controlled negative flow control system

In the design phase, combines the technical knowledge of each field to develop a consistent and better-performing overall system. The variable of the main pump and the action of the main valve spool are synchronized, so the operating sensitivity of the positive flow system is good. Quick and smooth motion is used to achieve the best working power.

— The performance of the whole machine is improved using advanced research and technology

Through the optimized matching of the engine, the main pump and the main valve, the control performance of the whole machine is greatly improved.For the first time in the industry, the function buffer valve system is used. Even in extremely cold weather, the reaction speed of the whole machine will not be reduced.While the impact of the whole machine remains optimal, there is no delay in starting and switching of the working device, which makes the flexibility, efficiency and energy saving of the whole machine during loading and unloading reach the leading level in the industry.

EFFICIENCY

Higher productivity and lower ownership operating costs

— Excellent performance and higher loading efficiency

The high-power engine is perfectly matched with the high-performance hydraulic system. Under heavy loading conditions, the main controller automatically adjusts the power and speed according to the change of the loading to ensure high output powerunder heavy load conditions, so as to improve the efficiency of the whole machine under heavy load conditions and increase the loading operation ability per unit time by 15%.

— Super digging force

On the basis of ensuring static digging force, we are committed to the development of dynamic digging force. In the case of encountering large resistance during the digging process, the system will automatically detect the resistance and adjust the output power to ensure the power adjustment is completed during the dynamic digging process.Strong power output is achieved.

— Lower fuel consumption

Due to the adoption of the latest technology and hydraulic system, the proven Isuzu engine have a good performance in terms of

hourly fuel consumption and fuel efficiency

In order to eliminate work fatigue and improve productivity, the noise rate in the cab is controlled at the low level. The cab is mounted on an elastic base to absorb the vibration of the digger. Rubber flanges support to have a apositive effect on noise reduction.

Related Keywords