Central Material Conveying and Vacuum Transport Systems in Plastic Industry Blowing Moulding

- Min. Order:

- 1 set

- Min. Order:

- 1 set

- Port:

- Shanghai, Guangzhou, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Supply Ability: | 8 Set/Sets per Month |

|---|---|

| Payment Type: | L/C,Western Union,D/P,T/T |

| Port: | Shanghai,Guangzhou, Shenzhen |

Material Conveying System

1. First step of factory automation to centralize material conveying systematically

2. Replacing single machine conveying; reducing the energy and labour cost

3. Normalizing production site to be in order, clean and tidy.

4. Easy use; High efficiency

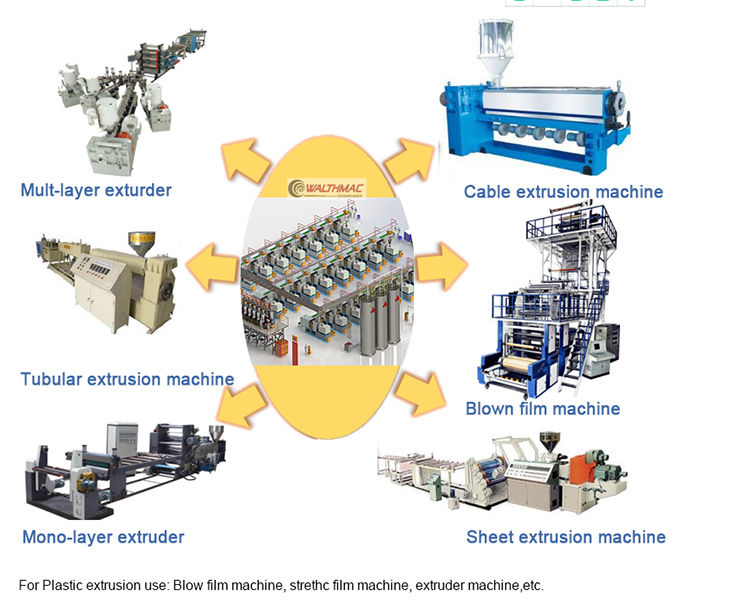

Applying to the whole field of plastic industry manufacturing plant.

For raw materials centralized & long distance conveying/transportation.

Centralized storage and conveying to avoid secondary pollution; achieve high efficiency, low cost; and dust & noise-free in workshop dramatically.

1. The whole conveying process is in a full- sealed loop, which prevents secondary pollution in production.

2. Easy use, high efficiency and stable working status, labor cost saving.

3. Long distance continuous transportation

4. Noise and dust-free working place.

5. Low energy consumption.

6. Automatically detection and re-filling.

7. Quality control improving.

Optional model and related parameters:

|

Model |

Output(kg/hr) |

Profile(mm) |

|

MTS-500-ACE |

Up to 500 |

1200*700*2000 *1

|

|

MTS-900-ACE |

Up to 900 |

1200*700*2000 *1

|

|

MTS-1500-ACE |

Up to 1500 |

1300*820*2000 *1

|

|

MTS-2000-ACE |

Up to 2000 |

1800*950*2000 *2

|

|

MTS-3000-ACE |

Up to 3000 |

2000*1100*2000 *2

|

|

MTS-5000-ACE |

Up to 5000 |

2100*1200*2100 *2

|

Note: The model with ACE means having the automatic dust removal device.

*1 means conveying by fan, *2 means conveying by vacuum pump.

Accept OEM & ODM order.

Based on our strong techinical strength, orders of customerized model or

special application model are acceptable. Our R&D dept can work for every

customer's special auto manufacturing requirement if needed.

Related Keywords