Control of Pipe Wall Thickness using Feeding Granular HDPE, uPVC, and PPR Gravimetric Dosing Systems

-

$8900.001-9 set

-

$8800.00≥10 set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

Products Description

The Gravimetric Dosing System revolutionizes plastic pipe manufacturing, delivering precise and consistent dosing for optimal efficiency and performance. It saves time, reduces costs, and eliminates errors, making it an invaluable asset in today's industry.

Technical Parameter

Control accuracy error | <0.3-0.5% |

Weighing resolution | 1/4000000 |

Control unit | Microprocessors,Adaptive algorithm |

Size | 665*345*775 mm |

Output | 1-350 kg/hr |

Operation Voltage | DC24V |

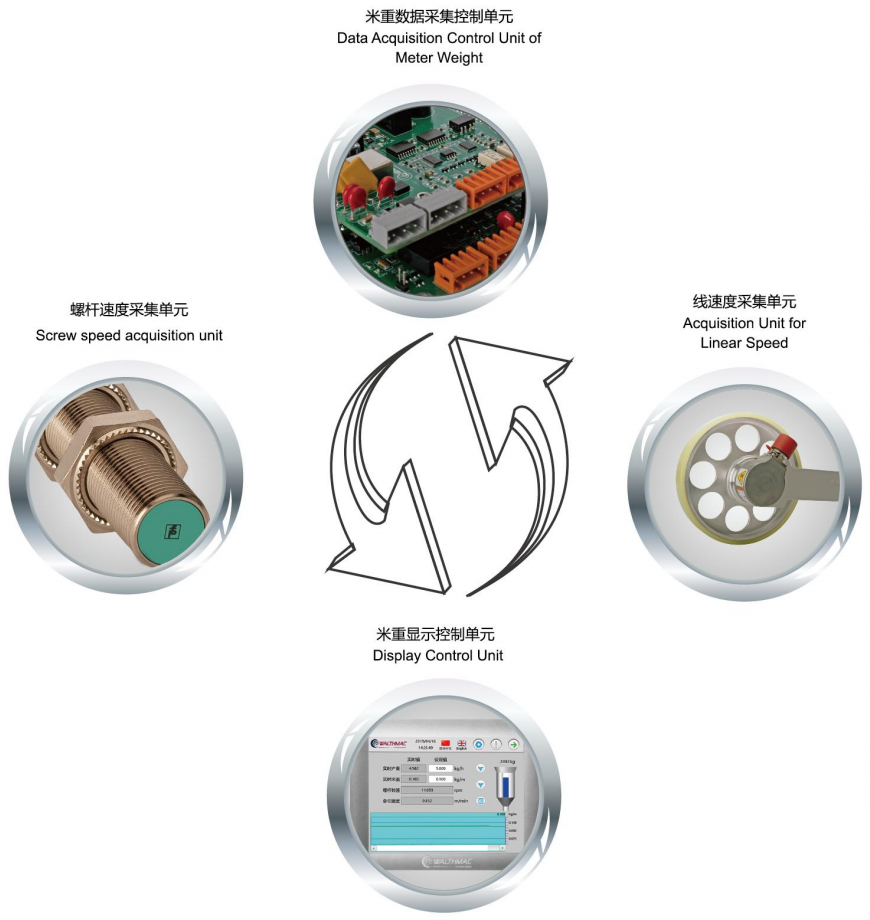

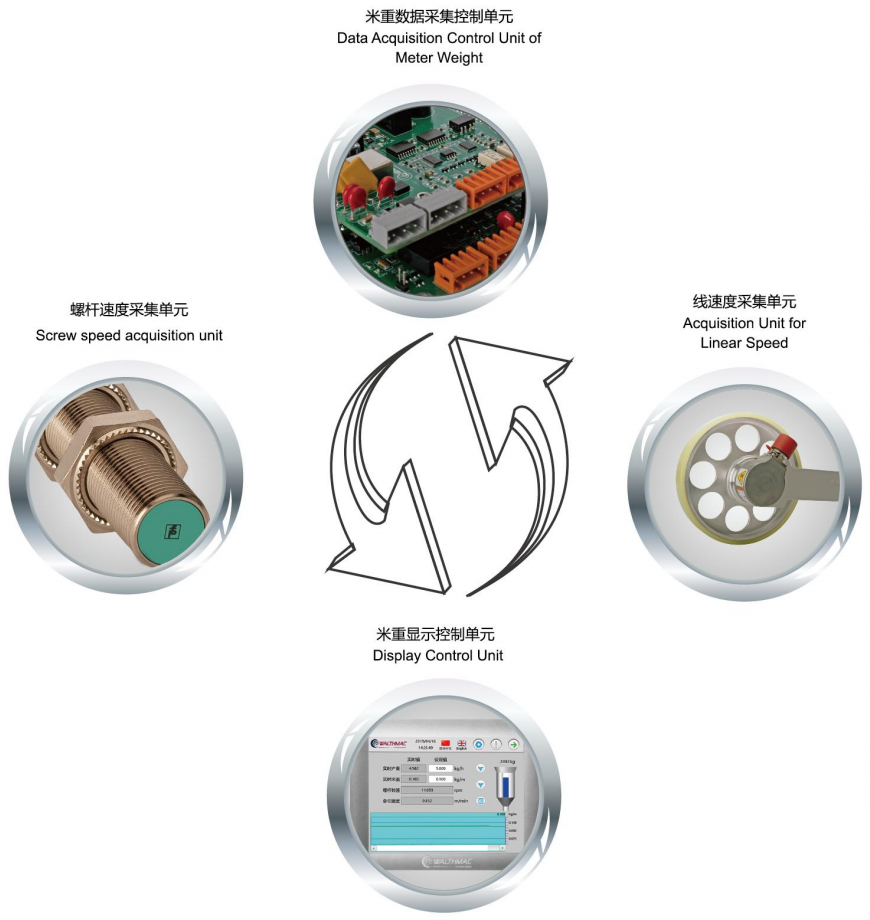

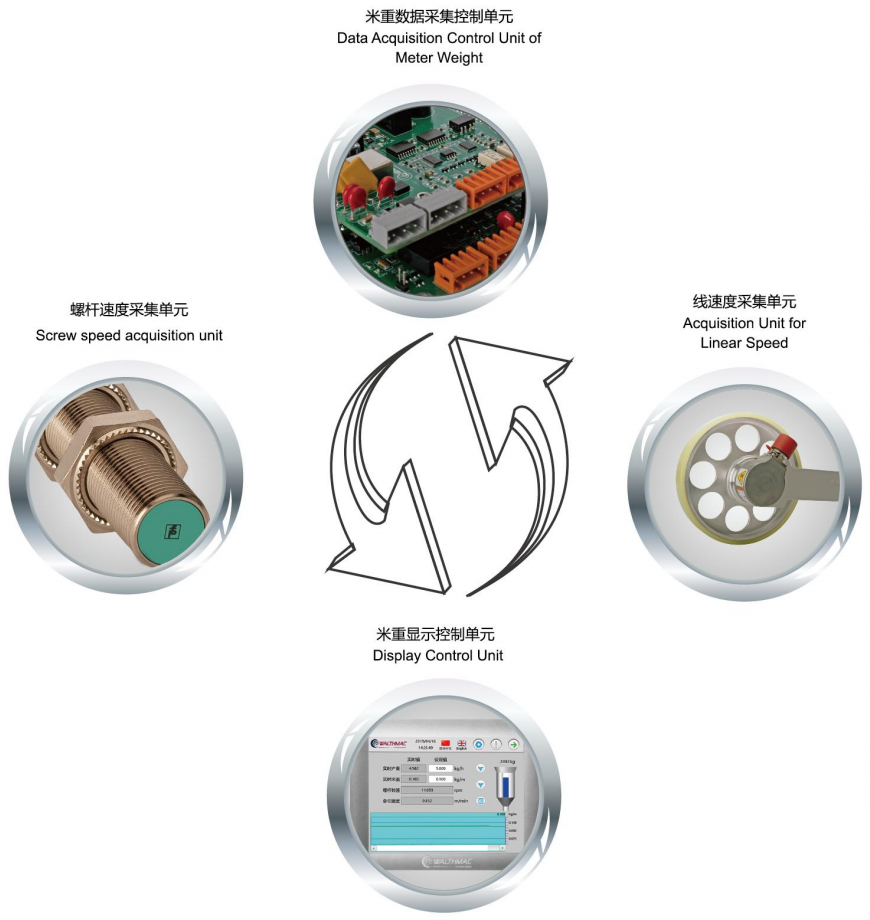

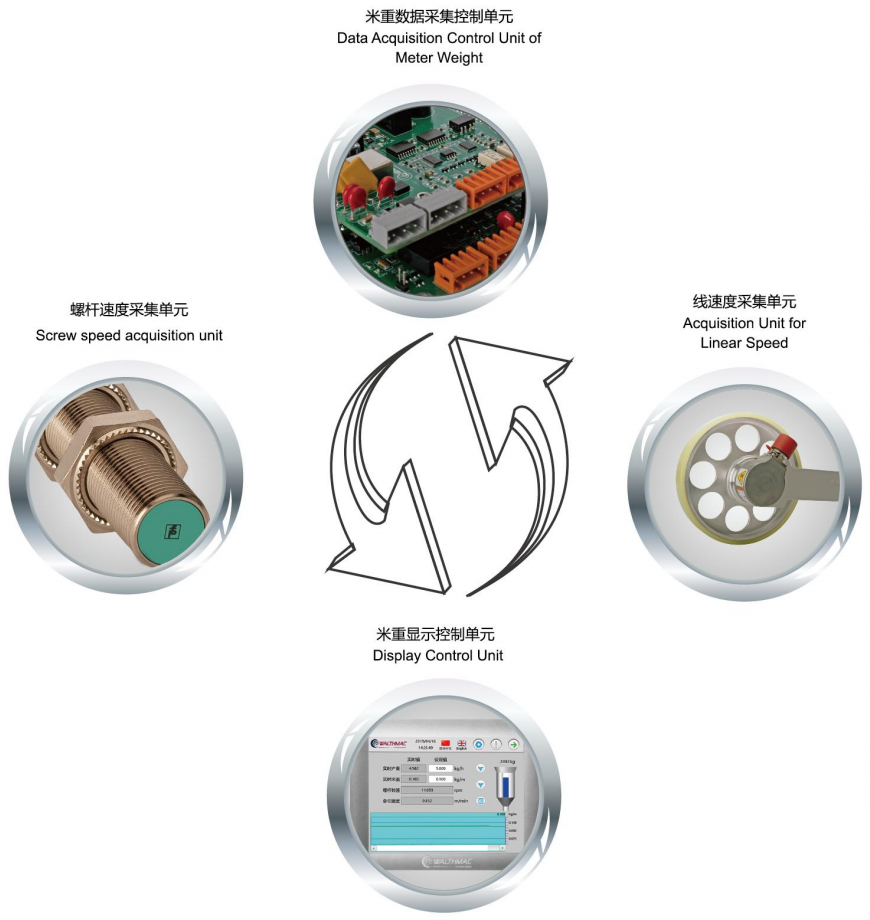

Main components

Advantage

1. Industry compliance: The system ensures compliance with industry regulations and standards by providing accurate dosing and documentation, enhancing product quality and consistency.

2. Cost savings: By minimizing material waste and errors, the system helps reduce production costs and improve the overall profitability of the manufacturing process.

3.Process optimization: It helps optimize the overall production process by ensuring precise material dosing, leading to improved productivity and performance.

4.Cost savings: By minimizing material waste and errors, the system helps reduce production costs and improve the overall profitability of the manufacturing process.

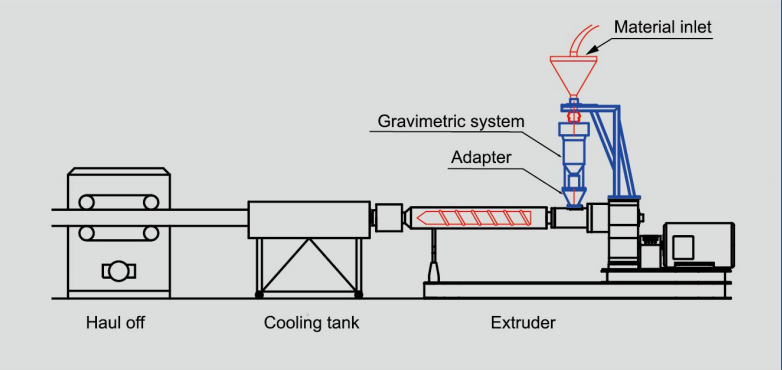

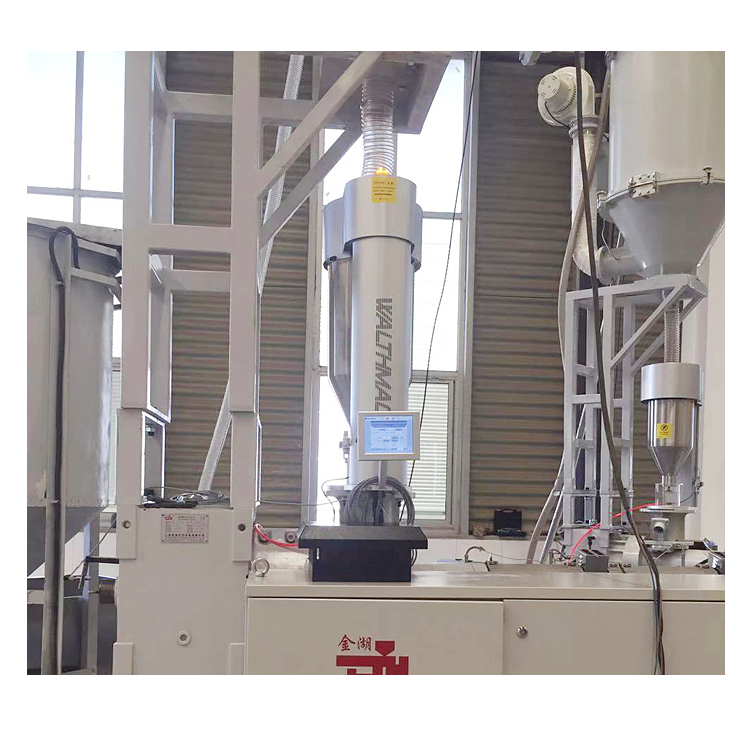

Installation

Before installation, ensure the extruder is powered off and disconnected. Attach the provided adapter and bracket to the extruder as instructed. Connect the system's components to the adapter securely, checking for any loose connections. Adjust as needed.

Applications

This exceptional dual-system application efficiently extrudes plastic pipes, demonstrating the team's innovative approach and expertise.

WalthMac Measurement&Control Technology Co., Ltd was founded in 2009.We have our own research and development team and base, established for 14 years, have provided products and services to over 800 customers both domestic and foreign.

After we setting the R&D center,we design and sell by ourselves.By receiving the feedback from customers who had deal with us,we keep innovating to improve the ability of machines.During 14 years,we had passed many international certifications such as CE,ISO,UNGM etc.

F&Q

1.Are you trade company or manufacturer?

We are manufacturer who designs and produces auxiliary equipment.

2.What's the delivery term you deal?

Usually deal with FOB,DAP.

3.What's the payment term ?

We deal with 30% prepayment by TT and get the rest before delivery.

Related Keywords

Related Keywords

You May Also Like

You May Also Like

-

Extrusion Production Line: Understanding Meter Weight Control and Gravimetric Systems

Gravimetric Dosing Units and Blenders: Precision in Liquid and Powder Handling

Ultrasonic HDPE Pipe Measurement Instrument: Accurate OD Diameter and Wall Thickness Gauge for Online Quality Checking

Efficient Systems for Plastic Recycling: Exploring Hopper Loaders and Loss-in-Weight Feeders

Central Material Conveying and Vacuum Transport Systems in Plastic Industry Blowing Moulding