Gravimetric Dosing Units and Blenders: Precision in Liquid and Powder Handling

$8600.00/set

- Min. Order:

- 1 set

- Min. Order:

- 1 set

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

Product Description

Product Description

Products Description

The Gravimetric Blender: an advanced blending tool extensively employed in the worldwide plastic industry. With its meticulous engineering, this device guarantees remarkable accuracy and efficiency when combining plastic materials. It caters to diverse mixing and blending needs, making it the favored option among industry experts.

Technical Parameter

Components | 4 components |

Maximum output | 300 kg/hr |

Feeding error | ±0.1-0.3% |

Weighing resolution | 1/2000000 |

Mixing chamber sensor | Material level sensor |

Certification | CE |

Adavantages

1. Precision: The blender ensures precise measurement and control of the materials being blended. By accurately weighing the components, it guarantees consistent and accurate blending ratios, resulting in high-quality end products.

2. Efficiency: With its state-of-the-art design and technology, the Gravimetric Blender optimizes the blending process,minimizing waste and maximizing productivity. It allows for quick and efficient material changes, reducing downtime and increasing overall production efficiency.

3. Flexibility: These blending devices provide a wide range of mixing and blending capabilities, allowing for the customization of blends to meet specific requirements. They can handle various types of materials, including powders, pellets, flakes, and additives, offering versatility in blending options.

4. Automation: Gravimetric Blenders are equipped with advanced automation features, such as programmable recipes and touch-screen interfaces. This automation streamlines operations, reduces human error, and enhances overall process control.

How to installation system

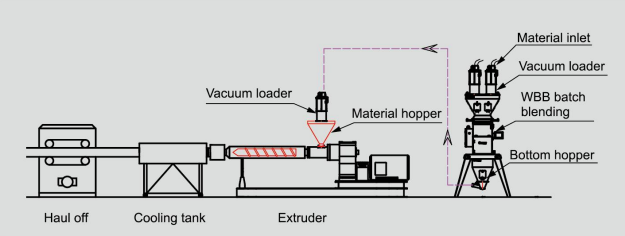

Offline installation

Setting up the Gravimetric Blender is a breeze, thanks to its intuitive interface. Once in place, this blending device effortlessly transfers materials via pipes, smoothly moving them from the lower hopper to the vacuum loader. This streamlined procedure exemplifies the efficiency and convenience offered by advanced technology.

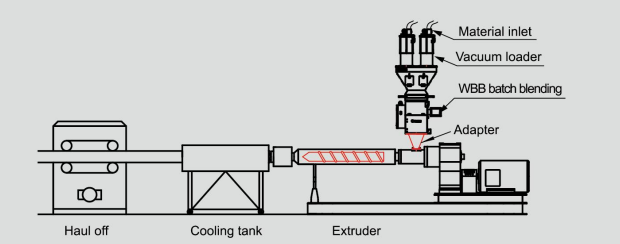

Online installation

Installing the Gravimetric Blender is a breeze due to its user-friendly interface. Once set up, the blender seamlessly transports materials through pipes, effortlessly moving them from the lower hopper to the vacuum loader. This streamlined process showcases the efficiency and convenience of cutting-edge technology

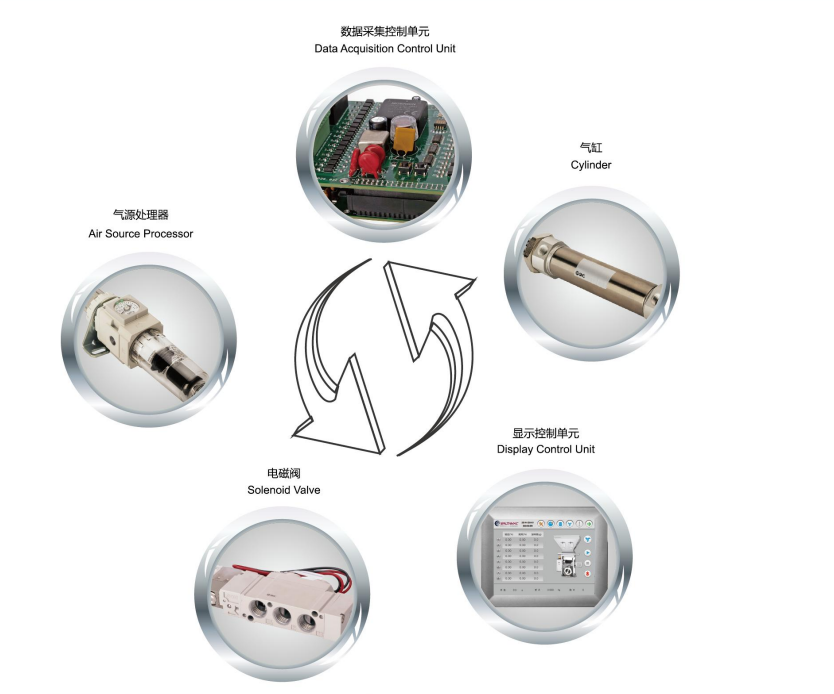

Main components

Applications

WALTHMAC was founded in 2009.It is a national high-tech enterprise that pursues the product design concept of "Product is Art". Our company focuses on automatic measurement and control equipment related to online measurement and control in plastic, food, pharmaceutical and other processing industries. Among them, Online Ultrasonic Thickness Measuring System and Gravimetric Control System and other products are integrated and used by many domestic plastic equipment manufacturers as standard configurations.

We concentrate on helping our client practicing the purpose of auto-manufacturing procedure ,therefore,to enhance quality standard,cost saving on materials and labour sources,sharply cut down the dependence on personal experiences of operator.Designed concept for 10 years service time,is our plan but serious promise to all Walthmac valuable clients.

Exhibition

Every year,the products are exported to Europe, Southeast Asia, the Middle East,

Australia, Africa,America and other countries and regions.

Australia, Africa,America and other countries and regions.

Related Keywords

Related Keywords

You May Also Like

You May Also Like

-

Extrusion Production Line: Understanding Meter Weight Control and Gravimetric Systems

Gravimetric Dosing Units and Blenders: Precision in Liquid and Powder Handling

Ultrasonic HDPE Pipe Measurement Instrument: Accurate OD Diameter and Wall Thickness Gauge for Online Quality Checking

Efficient Systems for Plastic Recycling: Exploring Hopper Loaders and Loss-in-Weight Feeders

Central Material Conveying and Vacuum Transport Systems in Plastic Industry Blowing Moulding