Impact Mill impact grinding impact grinder

-

$65432.00≥1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Transportation:

- Ocean, Land, Air, Express

Your message must be between 20 to 2000 characters

Contact Now| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

|---|---|

| Incoterm: | CFR,FOB,CIF,EXW,FAS,FCA,CPT,CIP,DDP,DDU |

| Transportation: | Ocean,Land,Air,Express |

Mianyang Liuneng Powder Equipment Co., Ltd. is a leading comprehensive service provider of powder equipment in the industry, headquartered in Mianyang City, Sichuan Province, China. The company provides customers with high-end powder processing equipment with grinding, conveying, and particle surface modification technology as its core. At the same time, it provides integrated powder engineering services from production line design, equipment manufacturing, installation and commissioning to production and delivery.

The equipment currently developed and issued by the company includes 10 series, more than 30 categories and more than 100 types of equipment, such as energy-saving jet mill, steam jet mill, high-efficiency micro moisture jet mill with drying function, control grind jet pulverizer, nano pulverizer, shaping mill, jet mill, impact mill, pneumatic conveying system, etc. We are a leading domestic technology and well-equipped powder equipment manufacturer. The product has been exported to more than 20 countries and regions including the United States, France, Germany, Japan, South Korea, Russia, etc.

Company pictures

Product Certification

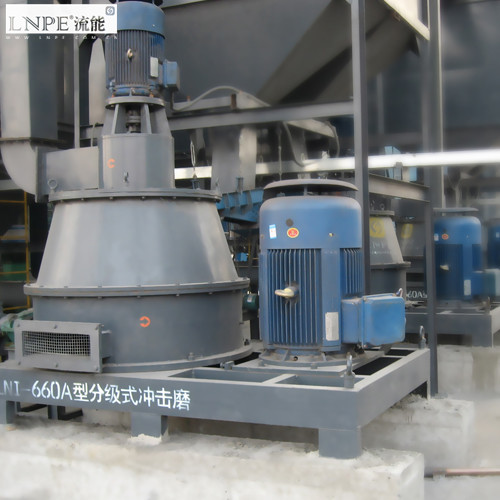

Product Description of LNI-660A

LNI-660A mechanical mill is an industrial-grade mechanical equipment designed for efficient and fine grinding, suitable for ultra-fine grinding of various materials. It is widely used in mining, building materials, chemical, metallurgy and other industries, and can process a variety of raw materials with high hardness such as ore, coal gangue, limestone, cement clinker, etc.

LNI-660A mechanical mill adopts advanced impact crushing and grinding technology. Through the interaction between the high-speed rotating hammer head and the liner fixed on the inner wall, the material entering the grinding chamber is strongly impacted, sheared and crushed, thereby achieving fine crushing of the material. In addition, the equipment is also equipped with an efficient grading system to ensure the uniformity and accuracy of the product particle size.

Application

Related Keywords