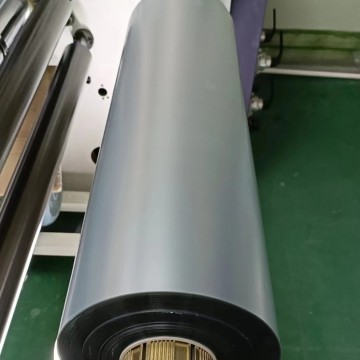

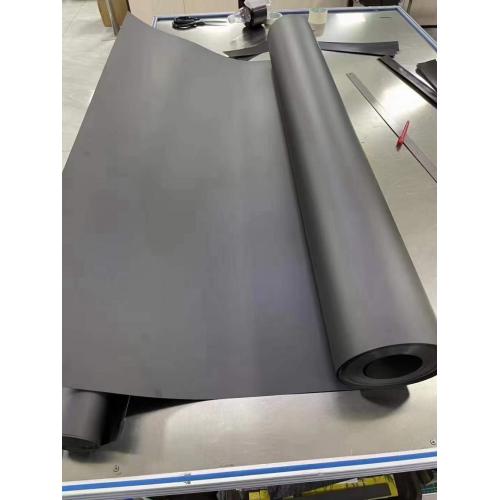

0.15-2mm PEEK Anti-corrosion Thin Film Max Width 1300mm

-

$250.00≥100 Kilogram

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- shanghai , guangzhou, shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000kgs/month |

| Supply Ability: | 10000kgs/month |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal,Others |

| Incoterm: | FOB,DDU,CFR,Express Delivery,CIF,DAF,EXW,FAS,DES,FCA,CPT,CIP,DEQ,DDP |

| Certificate: | ISO |

| HS Code: | 3920999090 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | shanghai ,guangzhou,shenzhen |

High Temperature Resistance PEEK Polyetheretherketone Film

0.15-2mm PEEK Anti-corrosion High Performance Thin Film Max Width 1300mm

PEEK film is an unfilled semi-crystalline film made of polymer. Here is the performance characteristics:

1.High purity, good stability, light weight, high mechanical strength.

2. Radiation resistance, hydrolysis resistance and extensive chemical resistance: insoluble in all common solvents-excellent resistance to acids, alkalis, lubricants and automotive fluids.

3. Excellent heat resistance: the relative thermal index is 220 ℃, which is available in the processing of lead-free solder up to 300 ℃

4. Excellent abrasion resistance: more than 3 times abrasion resistance than PI and PTFE, and the ultimate pressure speed under non-lubricated condition is 145MPa-m / min

5.Excellent barrier performance and low moisture absorption performance.

6. Excellent sound absorption properties: Unparalleled anti-noise fatigue performance, can withstand higher output power.

7. Excellent electrical insulation performance: high dielectric strength, stable dielectric performance under various temperature, frequency and temperature conditions.

8. Lightweight and good flame retardancy; high flame retardancy without using flame retardant additives

9. Inherently halogen free

10. Easy to process – can be laminated to other materials, thermoformed, metallised, coated, printed, stamped and die cut, welded and heat sealed and coated.

Application:

Electrical insulation

Aerospace insulation

Pressure sensitive tapes

Pressure sensor membranes

Printed circuit substrates

Acoustic speaker diaphragms

High temperature labels

Capacitors

Washers in high speed motors

Washers in mobile phone hinges

Direct thermal bonding of metal foil

Flexible surface heaters

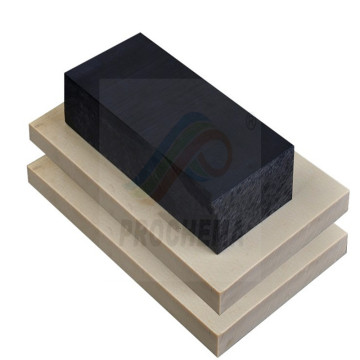

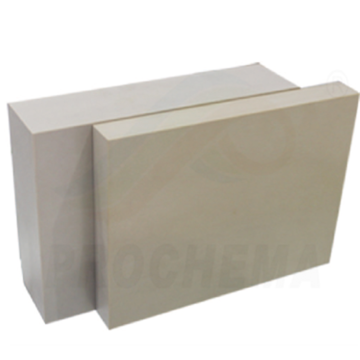

Material :

PEEK CF30: PEEK+30%Carbon fiber

PEEK LF30: PEEK+(10% Carbon fiber+10% Graphite+10% PTFE)

Specification :

PEEK film:0.08-0.75mm x 600mm PEEK sheet: thickness 1-100mm x Width 1000mm

PEEK rod: Dia 5-250mm x 1000-2000 PEEK tube: Dia0.5-580MMx100-2000mm

|

PEEK film is an unfilled semi-crystalline film made of polymer. Here is the performance characteristics: 1.High purity, good stability, light weight, high mechanical strength. 2. Radiation resistance, hydrolysis resistance and extensive chemical resistance: insoluble in all common solvents-excellent resistance to acids, alkalis, lubricants and automotive fluids. 3. Excellent heat resistance: the relative thermal index is 220 ℃, which is available in the processing of lead-free solder up to 300 ℃ 4. Excellent abrasion resistance: more than 3 times abrasion resistance than PI and PTFE, and the ultimate pressure speed under non-lubricated condition is 145MPa-m / min 5.Excellent barrier performance and low moisture absorption performance. 6. Excellent sound absorption properties: Unparalleled anti-noise fatigue performance, can withstand higher output power. 7. Excellent electrical insulation performance: high dielectric strength, stable dielectric performance under various temperature, frequency and temperature conditions. 8. Lightweight and good flame retardancy; high flame retardancy without using flame retardant additives 9. Inherently halogen free 10. Easy to process – can be laminated to other materials, thermoformed, metallised, coated, printed, stamped and die cut, welded and heat sealed and coated. Application: |

|

Electrical insulation Aerospace insulation Pressure sensitive tapes Pressure sensor membranes Printed circuit substrates Acoustic speaker diaphragms High temperature labels Capacitors Washers in high speed motors Washers in mobile phone hinges Direct thermal bonding of metal foil Flexible surface heaters |

PEEK CF30: PEEK+30%Carbon fiber

PEEK LF30: PEEK+(10% Carbon fiber+10% Graphite+10% PTFE)

Specification :

PEEK film:0.08-0.75mm x 600mm PEEK sheet: thickness 1-100mm x Width 1000mm

PEEK rod: Dia 5-250mm x 1000-2000 PEEK tube: Dia0.5-580MMx100-2000mm

Related Keywords