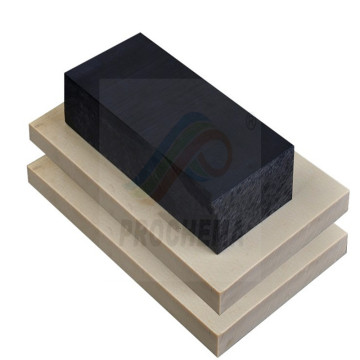

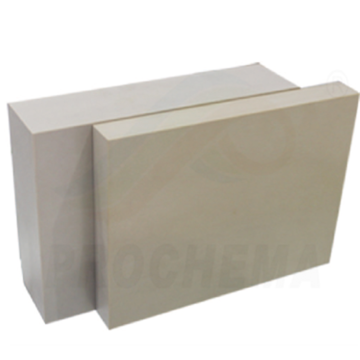

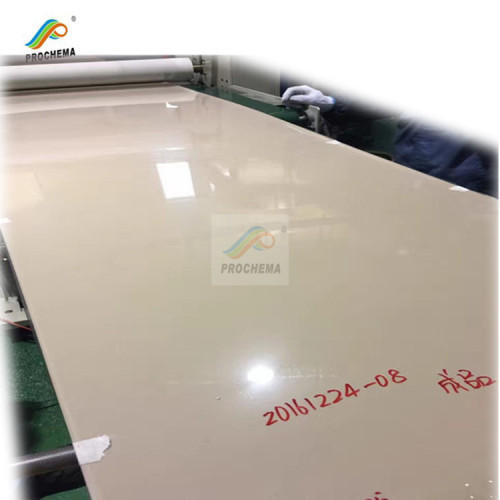

PEEK glass fiber filled reinforced extrusion sheet

-

$150.00≥100 Kilogram

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai, Shenzhen, Ningbo

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 2000kgs/week |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | ROHS FDA |

| HS Code: | 39269090 |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Shenzhen,Ningbo |

PEEK glass fiber filled reinforced extrusion sheet

Properties:

1 . Temperature

PEEK has a high glass transition temperature and melting point (334 °C), which is one of the reasons that it requires heat resistance can reliably use the application . Its load thermal deformation temperature up to 316 °C, continuous use temperature of 260 °C.

2 Mechanical properties

PEEK is both toughness and rigidity and balance of plastics. Particularly its excellent resistance to alternating stress fatigue is the most outstanding of all plastics , can be comparable with the alloy material.

3 self-lubricating

PEEK has outstanding sliding properties in all plastic , suitable for demanding low coefficient of friction and abrasion purposes. Especially carbon fiber, graphite certain percentage of each hybrid modified PEEK better self-lubricating properties .

4 chemical resistance ( corrosion )

PEEK has excellent chemical resistance, in the usual chemicals that can dissolve or destroy it only concentrated sulfuric acid , and its resistance to corrosion and nickel steel similar.

5 flame retardant

PEEK polymer is very stable , 1.45mm thick sample , without any flame retardant can achieve the highest standards .

6 peel resistance

PEEK excellent peeling resistance , it can be made of wire or coated with a thin wire , and can be used in harsh conditions .

7 fatigue resistance

PEEK has the best resistance to fatigue in all resin.

8 radiation resistance

The ability of strong resistance to γ radiation over the best general-purpose polystyrene resins radiation

resistance . You can still maintain γ radiation dose made up 1100Mrad good insulating ability when high performance wire .

9 hydrolysis resistance

PEEK and its composites from chemical effects of water and high-pressure steam , products made of this

material at high temperature and pressure water can still maintain excellent properties of continuous use

Properties of different materials PEEK sheet

| Item | Test Criteria or Instrument | Pure PEEK | PEEK & 30% Glass fiber | PEEK & 30% Carbon fiber | PEEK & 30% (Glass fiber & Carbon fiber & PTFE ) | Unit |

| Mechanical Properties | ||||||

| Density | ISO 1183 | 1.3 | 1.4 | 1.44 | 1.51 | g/m3 |

| Tensile strength | ISO 527-2/1B/50 | 100 | 155 | 220 | 134 | MPa |

| Tensile elongation | ISO 527-2/1B/50 | 34 | 2 | 1.8 | 2.2 | % |

| Bending strength | ISO178 | 163 | 212 | 298 | 186 | % |

| Compressive strength | ASTM D695 | 118 | 215 | 240 | 150 | Mpa |

| Rockwell scale | ASTM D785 | 99 | 103 | 107 | 102 | - |

| Friction coefficient | 0.30-0.38 | 0.38-0.46 | 0.28 | 0.18 | - | |

| Thermal Properties | ||||||

| Continuous use temperature | UL 7468 | 260 | 260 | 260 | 260 | °C |

| Heat deflection temperature | ASTM D648 | 315 | 315 | 293 | 163 | °C |

| Coefficient of thermal expansion | ASTM D695 | 4.7 | 2.2 | 1.5 | 2.2 | °C |

| Fire Resistance | UL94 | 1.5 | 1.5 | 1.5 | 0.75 | V-0@mm |

| Electrical properties | ||||||

| Dielectric strength | IEC 248 | kV/mm | ||||

| Dielectric constant | IEC 250 | N/a | ||||

| Surface Resistivity | 1015 | 1015 | 3 x 106 | 5 x 106 | Ω | |

| Color |

primary color Sallow |

|||||

Typical Applications

- Aircraft Hardware and fasteners

- Aircraft mechanical components

- Automotive electrical/electronic

- Transmissions/powertrain

- Semiconductor fabrication and testing

- Medical devices

- Dental cassettes and devices

- Oil and gas processing equipment

- Bearing retainers

- Gears

- Bushings

- Seals

- Thrust washers

PEEK CF30: PEEK+30%Carbon fiber

PEEK LF30: PEEK+(10% Carbon fiber+10% Graphite+10% PTFE)

Specification :

PEEK film:0.08-0.75mm x 600mm PEEK sheet: thickness 0.5-100mm x Width 1000mm x1000-2000mm

PEEK rod: Dia 5-250mm x 1000-2000 PEEK tube: Dia0.5-580MMx100-2000mm

|

Product Name

|

PEEK capillary tube

|

||

|

Material

|

PEEK5600G : 100%PEEK

|

||

|

Color

|

Natural

|

||

|

OD Φ1.6

|

ID Φ0.25 ,Φ0.50, Φ0.75, Φ1.0

|

OD Φ3.0

|

ID Φ2.67

|

|

OD Φ1.75

|

ID Φ1.4

|

OD Φ3.2

|

ID Φ1.0,Φ1.6

|

|

OD Φ1.8

|

ID Φ1.1, Φ1.4

|

OD Φ5.0

|

ID Φ2.5

|

|

OD Φ2.6

|

ID Φ2.4

|

OD Φ5.1

|

ID Φ1.1, Φ1.9

|

Related Keywords