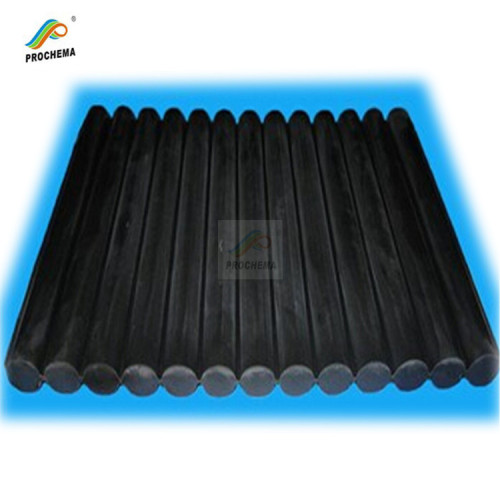

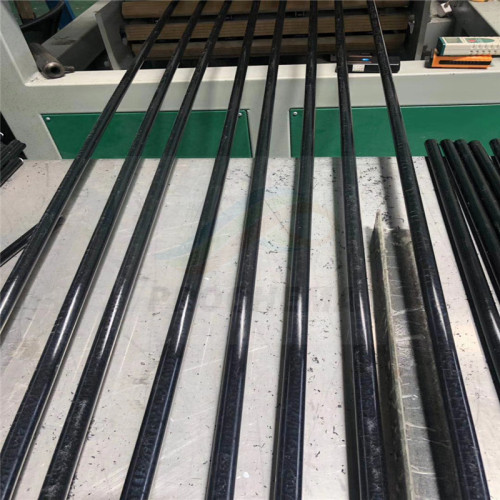

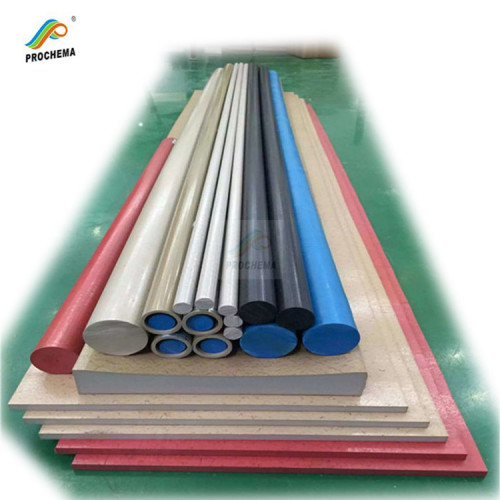

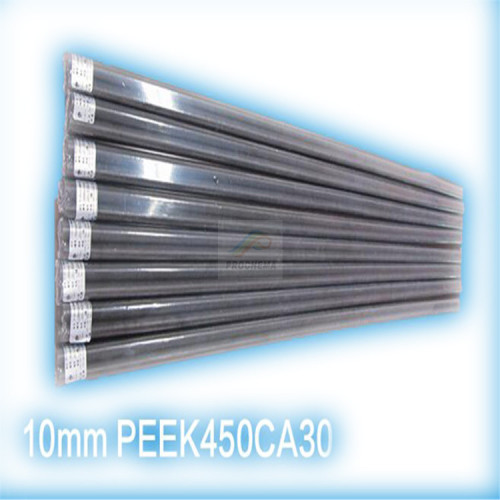

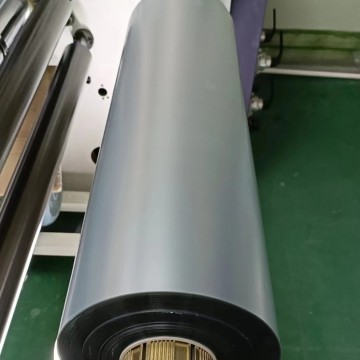

PEEK LF Radiation Resistance Carbon Graphite PTFE Rod

-

$200.00≥100 Kilogram

- Min. Order:

- 100 Kilogram

- Min. Order:

- 100 Kilogram

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| HS Code: | 39209990 |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Shenzhen |

PEEK is a high-temperature , high-performance specialty engineering thermoplastics . It has good mechanical properties and resistance to chemicals, abrasion -resistant properties , hydrolysis , etc. ; its light weight, selflubricating properties , due to the very good processing properties, can be filled with carbon fiber, such as molybdenum disulfide to further improve the lubricity and mechanical strength. PEEK plastic broad application space comes tohigh-tech industries in aviation, machinery electronics, chemical, automotive , etc., may be required for the manufacture of high mechanical parts such as gears, bearings , piston rings, support rings, seals ( letter ) , valves, wear rings.

Properties:

1 . Temperature

PEEK has a high glass transition temperature and melting point (334 °C), which is one of the reasons that it requires heat resistance can reliably use the application . Its load thermal deformation temperature up to 316 °C, continuous use temperature of 260 °C.

2 Mechanical properties

PEEK is both toughness and rigidity and balance of plastics. Particularly its excellent resistance to alternating stress fatigue is the most outstanding of all plastics , can be comparable with the alloy material.

3 self-lubricating

PEEK has outstanding sliding properties in all plastic , suitable for demanding low coefficient of friction and abrasion purposes. Especially carbon fiber, graphite certain percentage of each hybrid modified PEEK better self-lubricating properties .

4 chemical resistance ( corrosion )

PEEK has excellent chemical resistance, in the usual chemicals that can dissolve or destroy it only concentrated sulfuric acid , and its resistance to corrosion and nickel steel similar.

5 flame retardant

PEEK polymer is very stable , 1.45mm thick sample , without any flame retardant can achieve the highest standards .

6 peel resistance

PEEK excellent peeling resistance , it can be made of wire or coated with a thin wire , and can be used in harsh conditions .

7 fatigue resistance

PEEK has the best resistance to fatigue in all resin.

8 radiation resistance

The ability of strong resistance to γ radiation over the best general-purpose polystyrene resins radiation

resistance . You can still maintain γ radiation dose made up 1100Mrad good insulating ability when high performance wire .

9 hydrolysis resistance

PEEK and its composites from chemical effects of water and high-pressure steam , products made of this

material at high temperature and pressure water can still maintain excellent properties of continuous use

Properties of different materials PEEK rod

| Item | Test Criteria or Instrument | Pure PEEK | PEEK & 30% Glass fiber | PEEK & 30% Carbon fiber | PEEK & 30% (Glass fiber & Carbon fiber & PTFE ) | Unit |

| Mechanical Properties | ||||||

| Density | ISO 1183 | 1.3 | 1.4 | 1.44 | 1.51 | g/m3 |

| Tensile strength | ISO 527-2/1B/50 | 100 | 155 | 220 | 134 | MPa |

| Tensile elongation | ISO 527-2/1B/50 | 34 | 2 | 1.8 | 2.2 | % |

| Bending strength | ISO178 | 163 | 212 | 298 | 186 | % |

| Compressive strength | ASTM D695 | 118 | 215 | 240 | 150 | Mpa |

| Rockwell scale | ASTM D785 | 99 | 103 | 107 | 102 | - |

| Friction coefficient | 0.30-0.38 | 0.38-0.46 | 0.28 | 0.18 | - | |

| Thermal Properties | ||||||

| Continuous use temperature | UL 7468 | 260 | 260 | 260 | 260 | °C |

| Heat deflection temperature | ASTM D648 | 315 | 315 | 293 | 163 | °C |

| Coefficient of thermal expansion | ASTM D695 | 4.7 | 2.2 | 1.5 | 2.2 | °C |

| Fire Resistance | UL94 | 1.5 | 1.5 | 1.5 | 0.75 | V-0@mm |

| Electrical properties | ||||||

| Dielectric strength | IEC 248 | kV/mm | ||||

| Dielectric constant | IEC 250 | N/a | ||||

| Surface Resistivity | 1015 | 1015 | 3 x 106 | 5 x 106 | Ω | |

| Color |

primary color Sallow |

|||||

Applications:

Aviation Industry;

Medical Industries

Electricity & nuclear industr

Machine manufacturing Industries

Auto industry

Semiconductor production equipment parts

LCD production equipment parts

Cleaning jigs

Chemicals industry equipment parts

Precision equipment parts

Insulated terminals

Parts for food and beverage manufacturing equipment

Material :

PEEK CF30: PEEK+30%Carbon fiber

PEEK LF30: PEEK+(10% Carbon fiber+10% Graphite+10% PTFE)

Specification :

PEEK film:0.08-0.75mm x 600mm PEEK sheet: thickness 1-100mm x Width 1000mm

PEEK rod: Dia 5-250mm x 1000-2000 PEEK tube: Dia0.5-580MMx100-2000mm

Related Keywords