The application of PVF film in aviation interior decoration ,PVF membrane for aviation decoration

-

$3.50≥5000 Square Meter

- Min. Order:

- 5000 Square Meter

- Min. Order:

- 5000 Square Meter

- Transportation:

- Ocean, Land, Air, Express

- Port:

- shanghai, shenzhen, guangzhou

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Productivity: | 50000m2/month |

| Supply Ability: | 50000m2/MONTH |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

| Incoterm: | FOB,Express Delivery,CFR,CIF,DAF,EXW,DES,FAS,FCA,CPT,CIP,DEQ,DDP,DDU |

| Certificate: | ISO |

| Transportation: | Ocean,Land,Air,Express |

| Port: | shanghai,shenzhen,guangzhou |

Product Description

Product Description

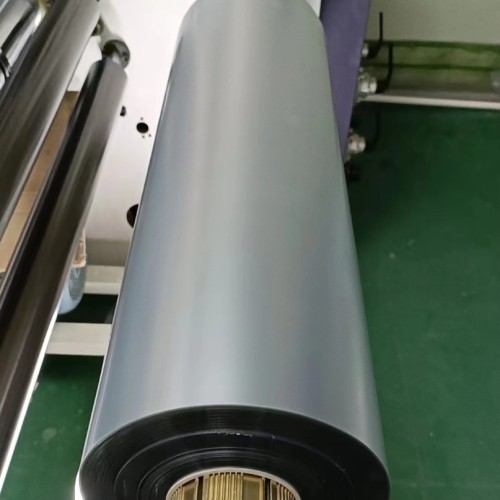

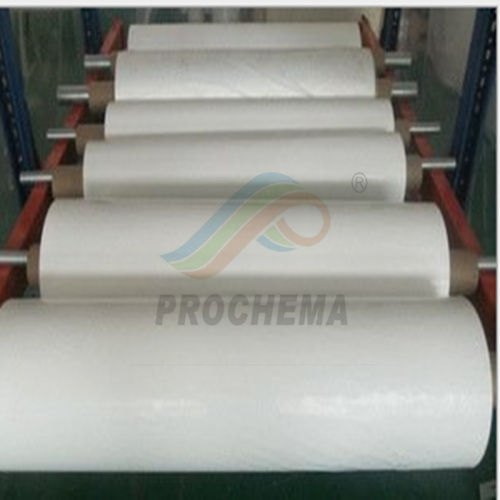

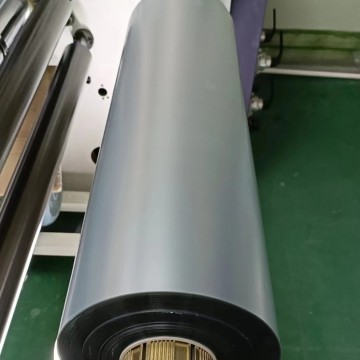

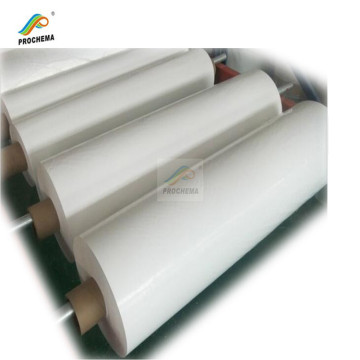

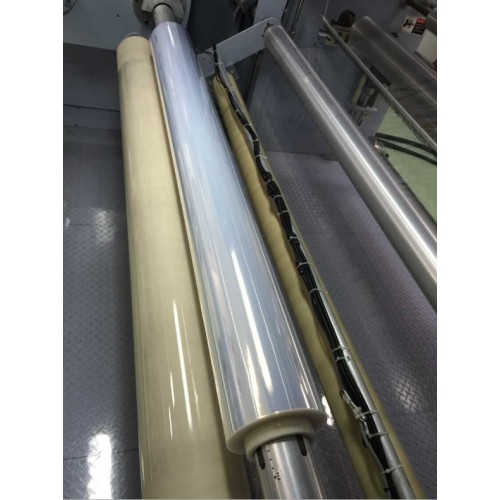

The application of PVF film in aviation interior decoration ,PVF membrane for aviation decoration

The application of PVF film in aviation interior decoration refers to the utilization of Polyvinylidene Fluoride (PVF) film in the design and manufacturing of aircraft interiors. PVF is a high-performance material known for its durability, resistance to chemicals, and excellent electrical insulation properties. In the context of aviation, it can be used for various applications such as:

1. **Interior Panels**: PVF film can be laminated onto core materials to create robust, lightweight panels for cabin walls, ceilings, and bulkheads.

2. **Floor Coverings**: It can be used in the production of floor coverings that need to withstand heavy foot traffic and potential exposure to harsh cleaning chemicals.

3. **Window Coatings**: PVF coatings can enhance the durability and performance of aircraft windows, providing protection against UV rays, scratches, and other environmental factors.

4. **Seat Fabrics and Covers**: PVF-based materials can be integrated into seat fabrics or covers for improved resistance to wear, tear, and staining.

PVF's combination of strength, flexibility, and high-quality surface finish makes it an attractive option for enhancing both the functionality and aesthetic appeal of aircraft interiors.

1. **Interior Panels**: PVF film can be laminated onto core materials to create robust, lightweight panels for cabin walls, ceilings, and bulkheads.

2. **Floor Coverings**: It can be used in the production of floor coverings that need to withstand heavy foot traffic and potential exposure to harsh cleaning chemicals.

3. **Window Coatings**: PVF coatings can enhance the durability and performance of aircraft windows, providing protection against UV rays, scratches, and other environmental factors.

4. **Seat Fabrics and Covers**: PVF-based materials can be integrated into seat fabrics or covers for improved resistance to wear, tear, and staining.

PVF's combination of strength, flexibility, and high-quality surface finish makes it an attractive option for enhancing both the functionality and aesthetic appeal of aircraft interiors.

Related Keywords

Related Keywords

You May Also Like

You May Also Like