PVF Anticorrosive Film Compounded With Steel Sheet

-

$5.00≥2000 Square Meter

- Min. Order:

- 2000 Square Meter

- Min. Order:

- 2000 Square Meter

- Transportation:

- Ocean, Land, Air

- Port:

- Shanghai, Shenzhen

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | L/C,T/T,D/P,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Certificate: | MSDS |

| HS Code: | 39209990 |

| Transportation: | Ocean,Land,Air |

| Port: | Shanghai,Shenzhen |

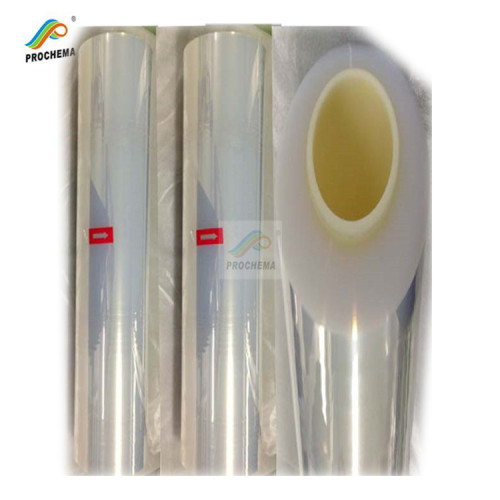

PVF Anticorrosive Film Compounded With Steel Sheet ,External Wall Protected Sheet

0.05X1500mm width

PVF film , also known as polyvinyl fluoride film (polyvinyl fluoride), referred to PVF. And a thermoplastic resin . Odorless, non-toxic white powder. Density 1.38. 240 °C above decomposition . Has a crystal structure, high transparency ( via UV ) ,

high electrical insulation properties, high toughness , good chemical resistance , anti-aging and resistance to corrosion.

And the ability -73 ~ +121 °C. Molecular fluorine and fluorocarbon copolymer extruded . Or copolymers of fluorine-containing fluorocarbon , greater than any polymer chemical bonding and structural stability. PVF film on the sunshine, chemical solvents, acid corrosion , moisture and oxidation resistance and durability is improved significantly . Film can be used as agricultural film, protective film material , packing grease and corrosive substances, can be used as electrical insulation materials.

PVF film wear resistance , anti- moisture penetration capability and scalability which can be increased to double.

PVF film does not contain plasticizers, color lasting stability, anti- bleaching agent, to prevent chalking and fungal growth . Repulsion of its large surface to prevent dust defiled , easy cleaning and maintenance .

Moreover , not only is the strongest detergent PVF film is not damaged .

From minus 70℃ to 110℃ , PVF film can guarantee excellent performance, the highest peak instantaneous temperature to 200 degrees and will not damage them . Also , PVF film without plasticizer , so it has excellent anti-aging properties

and in a very wide temperature range to maintain the toughness and bending. For testing institutions for PVF films for 20 years outdoor weathering tests.

Main Features :

Excellent anti-aging performance

PVF film performance:

|

Item

|

Specification

|

Result

|

TestMethod

|

||

|

Appearance

|

With smooth surface,no defects,cutting edge tidy,not damaged

|

OK

|

ASTM-E-284

|

||

|

Size

|

Thickness

|

μm

|

30±3

|

30

|

ASTM-D-2673

|

|

Length

|

M

|

1500±2

|

1500

|

ASTM-D-751

|

|

|

Width

|

mm

|

1400±3

|

1400

|

||

|

Density

|

g/cm3

|

1.38

|

OK

|

ASTM-D-792

|

|

|

Elongation(%)

|

MD

|

53~77

|

60

|

ASTM-D-638

|

|

|

TD

|

53~77

|

60

|

|||

|

TensileStrength(Mpa)

|

23℃/50%RH

|

MD

|

33~47

|

40

|

ASTM-D-638

|

|

TD

|

33~47

|

39

|

|||

|

Spring modulus

|

23℃/50%RH

|

Mpa

|

539~637

|

ASTM-D-790

|

|

|

Tear strength

|

Mpa

|

23℃/50%RH

|

343

|

ASTM-D-638

|

|

|

Impact strength

|

J/cm

|

23℃

|

12.2

|

ASTM-D-256

|

|

|

Coefficient of Linear Thermal Expansion

|

cm

|

23~60℃

|

8.3×105

|

ASTM-D-696

|

|

|

Shore Hardness

|

M

|

50~65

|

57

|

ASTM-D-2240

|

|

|

Water Absorption

|

%

|

24h,1/3"t

|

<0.00

|

ASTM-D-570

|

|

|

RecommendedTemperature

|

℃

|

-73~121

|

ASTM-D-1790

|

||

|

MeltingPoint

|

℃

|

240±12

|

240

|

ASTM-D-4894

|

|

|

Damp heat resistance

|

2000H

|

40~60℃/90%~95%RH

|

OK

|

ASTM-D-2126-04

|

|

|

O2 GTR(23℃/0%RH)

|

%

|

7mil·24h

|

>20

|

ASTM-D-3985

|

|

|

Ultraviolet radiation

|

2000H

|

OK

|

ASTM-D-4329

|

||

|

DielectricConstant

|

kHz

|

23℃

|

2.1

|

ASTM-D-150

|

|

|

Breakdown strength

|

V/mil

|

short time/3.2mm

|

3000

|

ASTM-D-149

|

|

|

Dielectric loss

|

kHz

|

23℃

|

<0.0002

|

ASTM-D-150

|

|

|

VolumeResistivity

|

kHz

|

23℃

|

≥0

|

ASTM-D-876

|

|

|

Fire Retardency

|

UL-94

|

V-O

|

ASTM-D-2863

|

||

|

ShelfLife

|

25℃/65%

|

12 months

|

ASTM-D-790

|

||

Main Application:

5.Combined with PET as the back of the solar cell protection plate

0.05mm PVF Transparent Gas Sample Bag Film0.05mm PVF Transparent Gas Sample Bag Film0.05mm PVF Transparent Gas Sample Bag Film0.05mm PVF Transparent Gas Sample Bag Film

Related Keywords