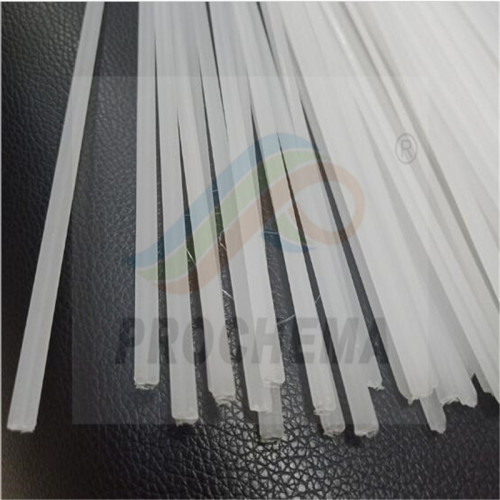

PVDF plastic welding rod

-

$60.00≥50 Kilogram

- Min. Order:

- 50 Kilogram

- Min. Order:

- 50 Kilogram

- Transportation:

- Ocean, Land, Air, Express

- Port:

- shanghai, shenzhen, guangzhou

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Payment Type: | T/T,L/C,D/P,D/A,Paypal |

| Incoterm: | FOB,CFR,Express Delivery,EXW,CIF,FAS,FCA,CPT,CIP,DEQ,DDP |

| Transportation: | Ocean,Land,Air,Express |

| Port: | shanghai,shenzhen,guangzhou |

PVDF plastic welding rod

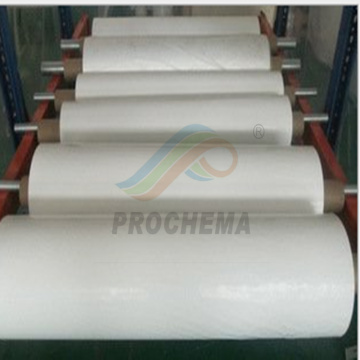

About PVDF Sheet & Rod:

PVDF, polyvinylidene fluoride, is a versatile fluoropolymer which is both strong and tough as reflected by its tensile properties and impact strengths. PVDF has excellent resistances to creep and fatigue. In thin sections, such as films, filament, and tubing, PVDF components are flexible and transparent.

Where load bearing is important, PVDF fluoropolymers are rigid and resistant to creep under mechanical stress and load. Because PVDF is stable to sunlight, and other sources of ultraviolet radiation, it is widely used as base resins for long-lasting exterior coatings. An additional advantage over other fluoroplastics is that PVDF can be welded into tanks for acid and corrosive chemical processing in elevated temperature environments.

Advantages:

PVDF fluoropolymers are rigid and resistant to creep under mechanical stress and load. Because PVDF is stable to sunlight, and other sources of ultraviolet radiation, it is widely used as base resins for long-lasting exterior coatings. An additional advantage over other fluoroplastics is that PVDF can be welded into tanks for acid and corrosive chemical processing in elevated temperature environments.

|

Item |

PVDF Sheet |

|

Color: |

White |

|

Density: |

1.8g/cm³ |

|

Heat resistance (continuous): |

150℃ |

|

Heat resistance (short-term): |

160℃ |

|

Melting point: |

175℃ |

|

Linear thermal expansion coefficient (average 23~100℃): |

130×10-6 m/(m.k) |

|

Average 23--150℃ |

145×10-6 m/(m.k) |

|

Flammability(UI94): |

V-0 |

|

Tensile modulus of elasticity: |

2300MPa |

|

Dipping into water at 23℃ for 24h |

0.01 |

|

Dipping into water at 23℃ |

0.0005 |

|

Bending tensile stress/ Tensile stress off shock |

50/- Mpa |

|

Breaking tensile strain |

>20% |

|

Compressive stress of normal strain-1%/2%: |

17/32 MPa |

|

Pendulum gap impact test |

10KJ/m2 |

|

Rockwell hardness: |

M75 |

|

Dielectric strength: |

18kv/mm |

|

Volume resistance: |

10 15Ω×cm |

|

Surface resistance: |

>10 15Ω |

|

Relative dielectric constant-100HZ/1MHz: |

7.4/6 |

|

Critical tracking index(CTI) |

600 |

|

Bonding capacity: |

0 |

|

Food contact: |

+ |

|

Acid resistance: |

+ |

|

Alkali resistance |

+ |

|

Carbonated water resistance: |

+ |

|

Aromatic compound resistance: |

+ |

|

Ketone resistance: |

0 |

Key Features:

- Mechanical strength and toughness ♦ High rigidity and high strength♦ Good mechanical performance, easy welding, thermoforming and other machining

- High abrasion resistance ♦ Toughness, wear resistance, excellent creep resistance

- High thermal stability

- High dielectric strength♦ Insulation resistance, high dielectric strength, low flammability

- High purity

- Readily melt processable

- Work temperature range -30-150 ° C

- Resistance to most chemicals and solvents ♦ Excellent chemical stability, good corrosion resistance

- Resistance to ultraviolet and nuclear radiation♦ Be stable for Oxide, Bromide and energy rays such as β and γ.

- Resistance to weathering ♦ Anti-aging properties, anti-ultraviolet

- Resistance to fungi

- Weldable♦ Good welding, thermal forming and machining

Applications:

♦ The best materials for petrochemical equipment, fluid handling systems as a whole or lined pumps, valves, piping, tanks and heat exchangers.

♦ To meet the requirements of anti-corrosion and fire-retardant, widely used in the semiconductor industry on high-purity chemical storage and delivery devices.

♦ Be used in the fields of electronics industry about LED related devices, chemistry equipment and food processing machinery.

♦ Also for metal reactor, metal anti-corrosion chemical containers lining

♦In environmental protection field, can be used for the lining of glassed steel reactor, plastic liner of enamel reactor and anti-corrosion lining of pipeline .

♦ Other pump parts, rotary disc, valve, stop valve, extraction centrifuge, cog wheel, pipe connections, slide, etc.

Specification:

Dia3-150mm Max length 6m

Related Keywords