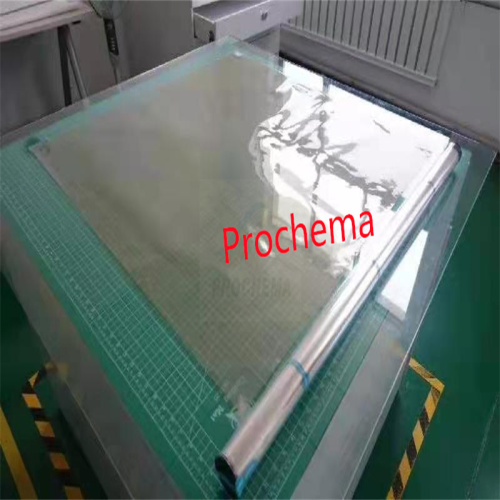

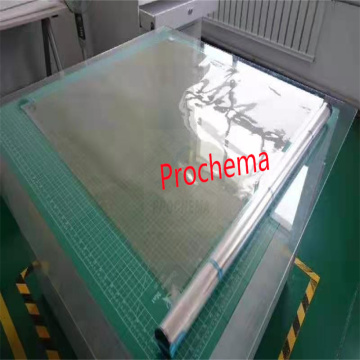

Dongyue DF28 PEM Chlor-alkali Membrane 1350x2465mm

-

$700.00≥34 Square Meter

- Min. Order:

- 34 Square Meter

- Min. Order:

- 34 Square Meter

- Transportation:

- Ocean, Land, Air, Express

- Port:

- SHANGHAI, GUANGZHOU, SHENZHEN

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 10000M2/MONTH |

| Supply Ability: | 10000M2/month |

| Payment Type: | L/C,T/T,D/P,D/A,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,DEQ,DDP,DDU,Express Delivery,DAF,DES |

| Certificate: | ISO |

| HS Code: | 3921909001 |

| Transportation: | Ocean,Land,Air,Express |

| Port: | SHANGHAI,GUANGZHOU,SHENZHEN |

Dongyue DF28 PEM Chlor-alkali Membrane 1350x2465mm

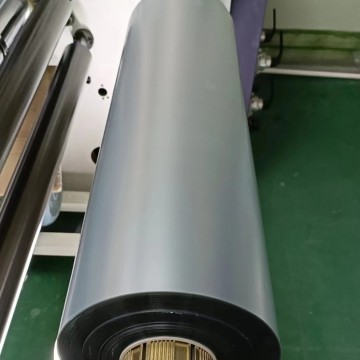

Chlor-alkali membrane, also known as chlorine-alkali membrane, is a type of membrane used in the chlor-alkali industry for the electrolysis of brine to produce chlorine gas, sodium hydroxide, and hydrogen gas. The membrane is a key component in the electrolysis process, as it allows for the selective transport of ions while preventing the mixing of the different electrolysis products.

Chlor-alkali membranes are typically made of a polymer material that is resistant to the harsh chemical environment of the electrolysis cell. The membrane is designed to selectively allow the passage of sodium ions and hydroxide ions, while blocking the passage of chlorine gas and hydrogen gas. This selective transport of ions helps to ensure the efficient production of chlorine gas and sodium hydroxide.

Overall, chlor-alkali membranes play a crucial role in the chlor-alkali industry by enabling the production of chlorine gas and sodium hydroxide through the electrolysis of brine. These products are essential for a wide range of industrial applications, including the production of PVC, paper, and textiles.

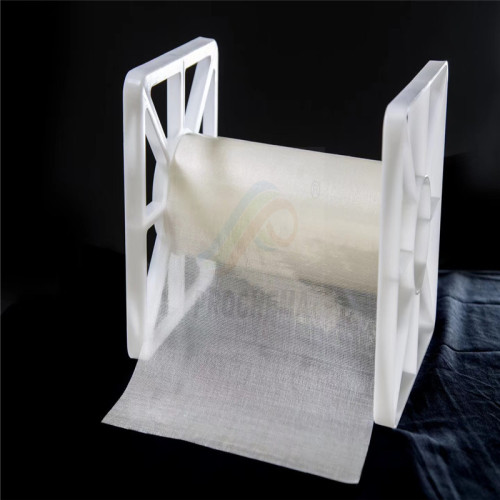

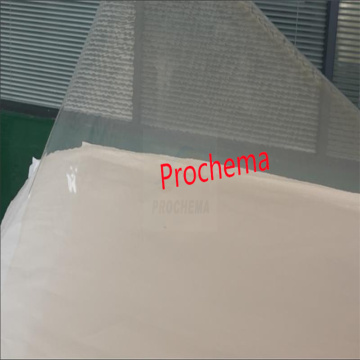

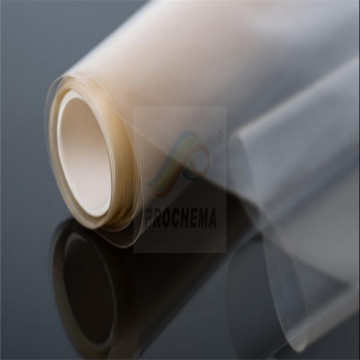

The Dongyue DF28 series of chlor-alkali membranes are high-performance ion exchange membranes specifically designed for use in electrolysis processes in the chlor-alkali industry. These membranes are made from a special polymer material that provides excellent chemical resistance, high ion conductivity, and long-term stability in harsh operating conditions.

The DF28 series membranes have a unique structure that allows for efficient transport of ions while preventing the passage of unwanted impurities, resulting in high purity and high efficiency in the production of chlorine, caustic soda, and other chlor-alkali products. These membranes are also highly durable and have a long service life, reducing maintenance costs and downtime.

Overall, the Dongyue DF28 series of chlor-alkali membranes are a reliable and cost-effective solution for chlor-alkali producers looking to improve the performance and efficiency of their electrolysis processes.

Chlor-alkali membrane is an ion exchange membrane used in the chlor-alkali process to produce chlorine, hydrogen and sodium hydroxide (caustic soda). These ion exchange membranes are made from perfluorosulfonic acid polymers, such as Nafion, that allow ions to pass through while blocking the passage of gases and larger molecules. This selective movement of ions can effectively separate the products of the electrolysis process. Its molecular structure consists of a perfluorinated main chain and a side chain containing sulfonic acid group (SO3H). The perfluorinated structure provides excellent mechanical, chemical and thermal stability. The sulfonic acid group allows ions to cross the membrane. Ion exchange site.

What are the main characteristics of chlor-alkali film?

The chlor-alkali film process has a variety of applications in the battery industry, including the production of certain types of batteries and the recycling of used batteries.

Related Keywords