WMT3015-AL Waterjet Cutter for Cutting Copper Metal Sheet

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 30 Days

- Transportation:

- Ocean

- Port:

- QINGDAO

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 200 SETS/YEAR |

| Supply Ability: | 200 SETS/YEAR |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE,ISO |

| HS Code: | 84649011 |

| Transportation: | Ocean |

| Port: | QINGDAO |

The water cutting machine is superior to other processing technologies such as flame cutting, plasma processing, laser processing, electric discharge machining, and milling and milling. At the same time, water cutting does not produce harmful gases or liquids and does not generate heat on the surface of the workpiece. It is truly versatile, efficient, and cold-cutting.

For example, in metal cutting, various processing methods coexist, including cutting tools, laser, flame cutting (plasma cutting), electric spark, wire cutting, water cutting and other processing methods. All kinds of cutting methods have their own advantages, and they all have certain limitations, each occupying a part of the market. However, among the many cutting methods, only the water cutting is a cold cutting, and the kinetic energy of the abrasive water jet is directly used.

The metal is cut to achieve the cutting purpose, no chemical change during the cutting process, no influence on the physical and chemical properties of the cutting material, no thermal deformation, narrow slit, high precision, smooth cut surface, clean and pollution-free, and can process traditional processing and Other processing methods are difficult to process or difficult to process materials, such as glass, ceramics, composites, reflective materials, chemical fiber, heat sensitive materials.

(1) The roughness of the cut metal is 1.6μm, and the cutting precision is ±0.10m, which can be used for precision forming cutting;

(2) No reflection effect and edge loss in the cutting of non-ferrous metals and stainless steel;

(3) One-shot cutting of carbon fiber composite materials, metal composite materials, metal composites with different melting points and non-metals;

(4) Cutting of low melting point and flammable materials, such as paper, leather, rubber, nylon, felt, wood, explosives, etc.;

(5) Cutting under special site and environment, such as underwater, flammable gas environment;

(6) Cutting of high hardness and insoluble materials, such as stone, glass, ceramics, cemented carbide, diamond, etc.

water jet cutting machine Features:

1. Numerical control of various complicated patterns;

2. It is cold cut, does not produce thermal deformation or thermal effect;

3. Environmental protection, no pollution, no toxic gases and dust;

4. Can process a variety of high hardness materials, such as: glass, ceramics, stainless steel, etc., or relatively soft materials, such as: leather, rubber, disposable diapers;

5. It is the only means of complex processing of complex materials and fragile porcelain materials;

6. The cut is smooth, no slag, no need for secondary processing;

7. Drilling, cutting and forming work can be completed at one time;

8. Low production costs;

9. High degree of automation;

10.24 hours of continuous work

WAMIT Cnc Glass Water Jet Cutting Machine WMT3020-AL is the top sell model in our company. it is with bridge type. cutting size is 2*3m ( 10'*6.56') . we can do 220V/380V and 415V for customers. this water jet cutting machine software is in English and Chinese, but we have imported software which can support more than 20 languages.

this abrasive waterjet cutting can cut rubber, pvc, glass, steel, marble, granite, brass, steel as follows.

Our waterjet cutting machine Advantages:

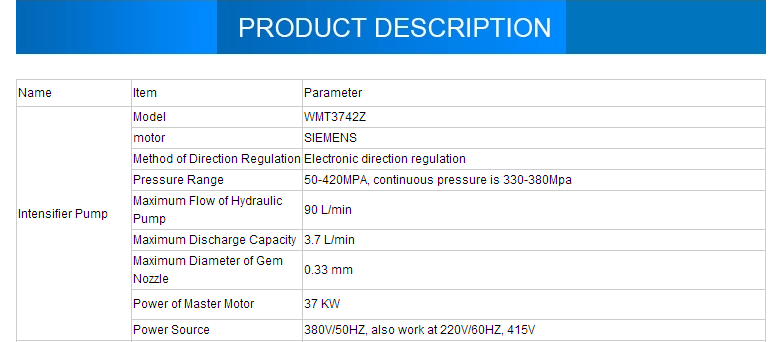

1.37KW SIEMENS motor

2.All electric components are Schneider brand

3.Can do special size and special design according to customer`s demand

4.Free abrasive sand feeding system

5.We have most convenient automatic abrasive sand removing and recycling system for any brand water jet cutting machine

6.Imported intensifier pump

7.Use 8mm steel to make the cutting table stronger and keep the precision time for whole life

8.Soft cover for linear guider or gear and rack, can effectively prevent dust

9.Install an automatic oil tank for cutting table , no need maintenance of linear guider

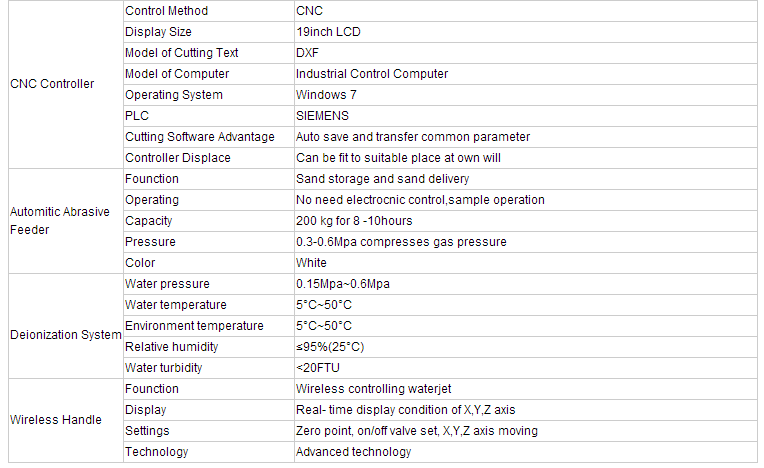

10.Legitimate WINDOWS 7 system and install the Chinese newest water jet cutting system

11.TBI linear guider and ball screw

12.Variable servo pump can reduce the electricity cost

13.We have agents in America, Russia, South Africa, Ecuador,UK, Argentina, Chile.Mexico,Australia,Saudi Arabia,Malaysia.Vietnam

14.We can make machine moving speed to 10-50m/min which will improve your cutting efficiency

15.We are finding agent all over the world

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

CUTTING SAMPLES:

OUR SERVICE OVER WORLD:

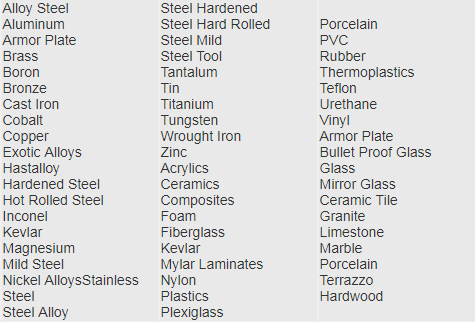

1. What kind of material does your water jet cutting machine can cut?

There are plenty materials our water jet cutting machine can cut, such as stone, ceramic, quartz, glass, foam, plastic,

rubber, copper, brass, aluminum, mild steel, pre-hardened steel, titanium, inconel and hastalloy

2. What's your cnc water jet cutting machine's max.cutting thickness?

Generally speaking, if cut steel the max thickness of our water jet cutting machine can be up to 240mm, but we suggest

cut not more than 150MM for smooth cutting. now our Z axis distance is 170mm, we can do special for customers.

3. How we supply after-service?

Some countries we have after-service department, we will provide local service, if have no local service,

we will arrange engineer for overseas installation and training. The installation and training time is generally 7-10 days.

And we also can provide installation videos.

4. What's your delivery time?

Generally speaking is 30 days. if have stock, 15 days.

5. if you are manufacturer or trader?

we are factory, and our factory is in JINAN city, China.

6. what's your warranty?

2 years (2500 hours).

Related Keywords