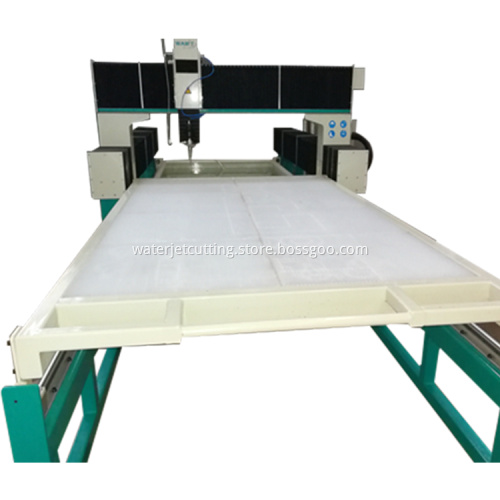

Sponge CNC Water Jet Cutting Machine

-

USD45000≥1 Set/Sets

- Payment Type:

- L/C, T/T

- Incoterm:

- FOB, CFR, CIF, EXW

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 10-30 Days

- Transportation:

- Ocean, Land

- Port:

- QINGDAO

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|---|

| Productivity: | 200 SETS/YEAR |

| Supply Ability: | 200 SETS/YEAR |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW |

| Certificate: | CE |

| HS Code: | 84649011 |

| Transportation: | Ocean,Land |

| Port: | QINGDAO |

WAMIT Sponge cnc Water jet Cutting Machine WMT2515-AL is with 1500*2500MM cutting size and 60k psi pressure. its cutting accuracy can be 0.05mm. can cut all shapes on all materials. this waterjet cutting machine software is in English and Chinese, but we have imported software which can support more than 20 languages.

this pure water waterjets can cut foam, sponge, EVA, leather, if with abrasive sand, it can cut rubber, pvc, glass, steel, marble, granite, brass, steel and so on.

we use SCHNEIDER electric components and SIEMENS PLC and SIEMENS Motor. with China best quality.

A. cutting table

1. Machine style: Bridge type

2. Processing dimension:1500mm×2500mm

3. Z-axis journey is 170mm

4. Control accuracy: ±0.01mm

5. Cutting accuracy: ±0.1mm

6. three-axis control, Auto zero positioning

7. Way of drive : Servo ( drives and motors are from Japan YASKAWA )

8. All screw and linear guide are TBI brand from Taiwan and we install a oil tank to make the linear guider and ball screw keep precision longer.

9.seperated body

X beam of cutting table applies 8mm steel that can make the accuracy longer. Support beam use 10mm steel, and the water tank is made by 6mm steel.

10. Use soft cover which can protect linear guider and ball screw better.

11.Use flow type abrasive sand hopper, it will be more stable and not easily be broken.

12. With a lubrication oil pump which can automatically supply oil to linear guider, so that the linear guider needn`t maintenance always.

13. There are 4 screws of each line of cutting table which can adjust the table flat a little , so that adjust the accuracy.

B. choice 1: waterjet pump 420mpa

1.Type of pressurization is hydraulic. (The water is pressurized by using the fluid pressure intensification principle).

2.Max. oil discharge is 90 L/min

3.Max. water discharge is 3.8L/min

4.Max. diameter of orifice is 0.33mm

5.Max. operating pressure is 420MPa(60000 psi)

6.Continuous operating pressure is 350-380MPa

7.Power requirement : 37KW, 3 phrase, 380V/50HZ, can do 220V/415V.

8.Type of shift is electronic

9.maintenance free accumulator whose capability is 1.0L Imported from TAIWAN

10.Intensifier is imported from USA

11.With SIEMENS motor and SIEMENS PLC and the motor is variable pump so that can reduce using cost.

12.all electric components are Schneider brand.

choice 2: 11.5kw direct drive pump. model: WMT SDD 15.( can save at least 50% electricity cost)

continuous working pressure : 36000-40000psi

max pressure: 46000psi

Orifice diameter: 0.3mm

water dischage: 2.5L/MIN

Water income pressure: 0.4mpa

motor power: 11.5kw

pump size: 1250*660*950mm

choice 3: 17 kw direct drive pump. model: WMT SDD 22 ( can save at least 50% electricity cost)

continuous working pressure : 36000-40000psi

max pressure: 46000psi

Orifice diameter: 0.3mm

water dischage: 3.7L/MIN

Water income pressure: 0.4mpa

motor power: 17kw

380V,50HZ,3 PHRASE

C. CNC controller

1. CNC control, apply 21 inch LCD

2. Adopt specialized WEIHONG water jet cutting software, have autosave function for next operation.

3. Apply SIEMENS PLC instead of relay, buttons are Schneider

4. Legal Windows 7 based, Support DXF file and any auto programming software to produce NC code

D. abrasive sand feeding system

Other optionals please ask us freely. we can do special design. like 1. revert table, 2. height tracking, 3. direct drive pump, 4. fast speed function can get 30m/min machine moving speed,4.movable loader, 5. turn over cutting table and so on.

Our waterjet cutting machine Advantages:

1.37KW SIEMENS motor

2.All electric components are Schneider brand

3.Can do special size and special design according to customer`s demand

4.Free abrasive sand feeding system

5.We have most convenient automatic abrasive sand removing and recycling system for any brand water jet cutting machine

6.Imported intensifier pump

7.Use 8mm steel to make the cutting table stronger and keep the precision time for whole life

8.Soft cover for linear guider or gear and rack, can effectively prevent dust

9.Install an automatic oil tank for cutting table , no need maintenance of linear guider

10.Legitimate WINDOWS 7 system and install the Chinese newest water jet cutting system

11.TBI linear guider and ball screw

12.Variable servo pump can reduce the electricity cost

13.We have agents in America, Russia, South Africa, Ecuador,UK, Argentina, Chile.Mexico,Australia,Saudi Arabia,Malaysia.Vietnam

14.We can make machine moving speed to 10-50m/min which will improve your cutting efficiency

15.We are finding agent all over the world

|

|

|

CUTTING SAMPLES:

OUR SERVICE OVER WORLD:

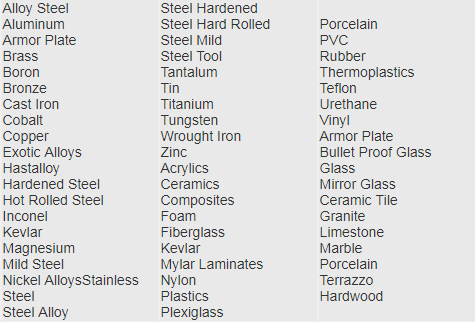

1. What kind of material does your water jet cutting machine can cut?

There are plenty materials our water jet cutting machine can cut, such as stone, ceramic, quartz, glass, foam, plastic,

rubber, copper, brass, aluminum, mild steel, pre-hardened steel, titanium, inconel and hastalloy

2. What's your cnc water jet cutting machine's max.cutting thickness?

Generally speaking, if cut steel the max thickness of our water jet cutting machine can be up to 240mm, but we suggest

cut not more than 150MM for smooth cutting. now our Z axis distance is 170mm, we can do special for customers.

3. How we supply after-service?

Some countries we have after-service department, we will provide local service, if have no local service,

we will arrange engineer for overseas installation and training. The installation and training time is generally 7-10 days.

And we also can provide installation videos.

4. What's your delivery time?

Generally speaking is 30 days. if have stock, 15 days.

5. if you are manufacturer or trader?

we are factory, and our factory is in JINAN city, China.

6. what's your warranty?

2 years (2500 hours).

Related Keywords