machine for small business pine oil pressing machine

- Delivery Time:

- 20 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Sichuan, China (Mainland) |

|---|

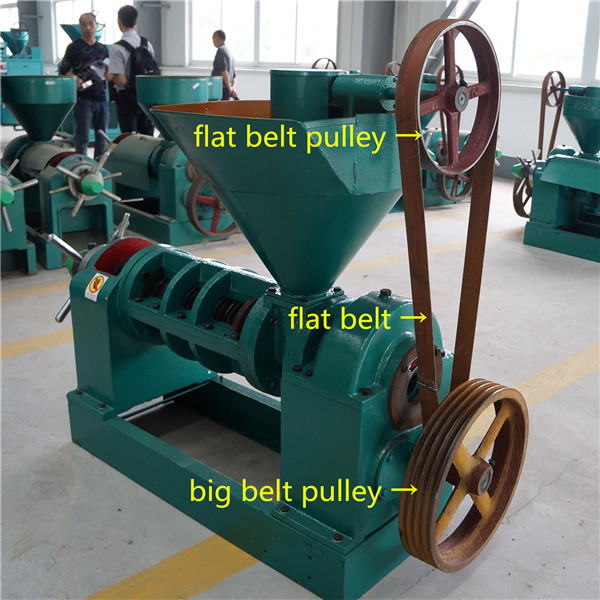

Product Description Product Description oil processing plant sunflower export oil machinery YZYX95 has Advantages: 1. Easy operating and small size, saving land, labor and energy consumption 2. Big pressing force in the chamber, making high oil output 3. Long-term continuous work, bring better economic benefit to user 4. Good quality and long durability, made of the most suitable material with refined treatments to ensure more than 10 years using 5. Wearing parts can be dismountable 6. Different design in squeeze chamber for both cold and hot pressing 7. Bevel gear technology make good performance when operating Picture Details

Product Description Product Description oil processing plant sunflower export oil machinery YZYX95 has Advantages: 1. Easy operating and small size, saving land, labor and energy consumption 2. Big pressing force in the chamber, making high oil output 3. Long-term continuous work, bring better economic benefit to user 4. Good quality and long durability, made of the most suitable material with refined treatments to ensure more than 10 years using 5. Wearing parts can be dismountable 6. Different design in squeeze chamber for both cold and hot pressing 7. Bevel gear technology make good performance when operating Picture Details

Specifications & Oil Yield Efficiency

Specifications & Oil Yield Efficiency Main Specifications | ||||

Product Model | YZYX95 | |||

Processing Capacity(T/24H) | 3.5T/24H | |||

Processing Capacity (KG/H) | 145KG | |||

Oil Content of Dry Cakes (%) | ≤8% | |||

Power Required (KW) | 7.5KW or 11KW | |||

Voltage | 380V/50HZ | |||

Measurement (L*W*H)(mm) | 1620*580*1165mm | |||

Spiral axes rotate speed (r/min) | 26-36 | |||

Weight (KG) | 528KG | |||

Main Oil Plants | ||||

Oil Plants | Processing Capacity (T/24HRS) | Oil Content of Dry Cakes (%) | Oil yield Efficiency (%) | Electricity Consumption(KW*H/T) |

Rapeseed | 3.5-4 | ≤8.0 | ≥80 | ≤35 |

Cottonseed | 3.5-4 | ≤7.5 | ≥75 | ≤55 |

Soybean | 3.2-3.5 | ≤7.0 | ≥65 | ≤52 |

Peanut | 3.5-4 | ≤8.0 | ≥91 | ≤35 |

Certificate Shows

Certificate Shows

1. 30 years' manufacturing experiences 2. Covering an area of 100000 square meters, with more than200 staffs, 10% are engineer and technician. 3. Comply IS09001: 2008 management system, in a leading position in China oil press industry. 4. We are manufacturer with export right, provide overseas clients with prompt delivery and professional after-sale service

1. 30 years' manufacturing experiences 2. Covering an area of 100000 square meters, with more than200 staffs, 10% are engineer and technician. 3. Comply IS09001: 2008 management system, in a leading position in China oil press industry. 4. We are manufacturer with export right, provide overseas clients with prompt delivery and professional after-sale service Fairs Communication

Every year, Guangxin will attend the biggest international fair held in China each April and October -Canton Fair, meet lots of professional purchasers. We also attended other professional fairs held in Moscow, Vietnam and Australia. Our oil press machine attracted large numbers of visitors with its wide applicability and superb craft. Packaging & Shipping Payment and Transportation

Every year, Guangxin will attend the biggest international fair held in China each April and October -Canton Fair, meet lots of professional purchasers. We also attended other professional fairs held in Moscow, Vietnam and Australia. Our oil press machine attracted large numbers of visitors with its wide applicability and superb craft. Packaging & Shipping Payment and Transportation

1. MOQ: | 1 Piece |

2. Quote Category: | FOB/CIF/EXW/FCA/DAF |

3.Payment Method: | T/T, L/C, D/A, D/P, Western Union, Money Gram, PayPal |

4. Payment Terms: | 30% deposit and 70% balance before delivery by T/T |

5. Packaging Details: | oil processing plant sunflower export oil machinery YZYX95 is packed with fumigated wooden packing, standard export packing, or as customer's request |

6. Delivery Time: | 20 days after payment received |

7. Port of Loading: | Shanghai or Guangzhou or as customer's request |

8. H.S. Code: | 84792000 |

9. Supply Capacity | 600 Pieces/Month |

FAQ FAQ 1. If I don't know how to operate this machine? How can I do? Our machine has been tested OK and fully assembled before shipping, customer just needs to make2~4 hours wear-in and then can work. 2. What's wear-in for new machine? Using 10 KG oil cake + 1KG sand + 1KG water, mix them, put in oil press, wear in 3~4hs. 1. 1st hour, adjust oil cake thickness as 3mm. 2. 2nd hour, adjust oil cake thickness as 2.5mm. 3. 3rd hour, adjust oil cake thickness as2 mm. 3. Why Feeding blocked and no oil comes out? 1. The work-sections of squeeze loops and squeeze spirals are coarse. 2. Oil plants in the press chest mixed with oil. 3. Gaps between the squeeze bars and oil grooves on the squeeze loops are blocked. 4. Oil plants have high oil content; need more oil channels to discharge the oil. 5. Oil plants are too dry when press in hot way. 4. What is the Moisture and temperature of oil plants to press? (For reference)

Items | Rapeseed | Groundnut | Cotton seed | Tung seed | Soybean (hot pressing) | Soybean (cold pressing) |

Moisture (%) | 1~2 | 1~2 | 2~2.5 | 2~2.5 | 1.5~2.5 | 8~10 |

Temp. (°C) | 130-135 | 120-125 | 120-130 | 110~120 | 120-125 | Normal temp. |

Wearing parts | Replacement period |

Squeeze loop & loop of the cake out | Run for 24hs, should replace 2 months |

Squeeze spiral & spiral of the cake out | Run for 24hs, should replace 1 month |

The accessory in the deceleration part | 10000hs |

Related Keywords