conductive AgNW film for EMI shielding

- Delivery Time:

- 7 Days

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China (Mainland) |

|---|

Product Description

Product Description

AgNWs-Film Applications: AgNWs-Film can be widely used in display device(LCD and electroluminscent display), touch screen(mobile phone, notebook computer, industrial equipment, etc.), thin film solar cell, OLED lighting, wearable electronics, flexible electronics and other electronic products. Features:

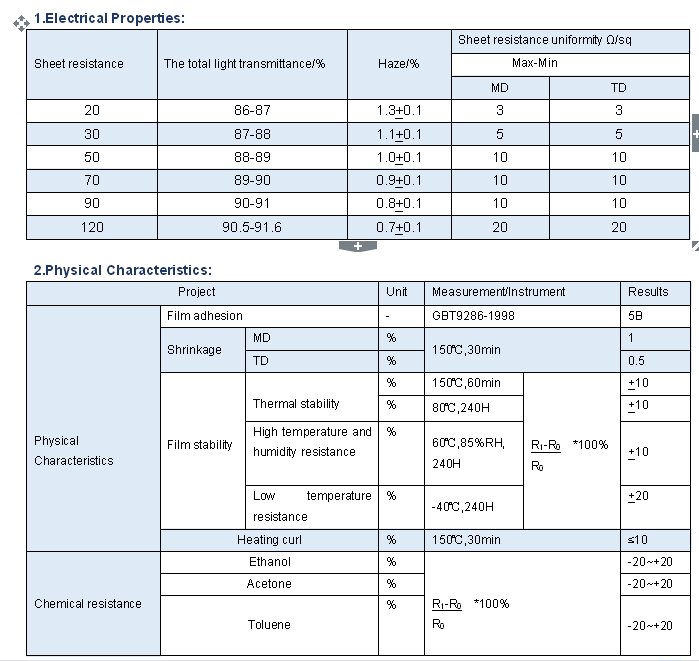

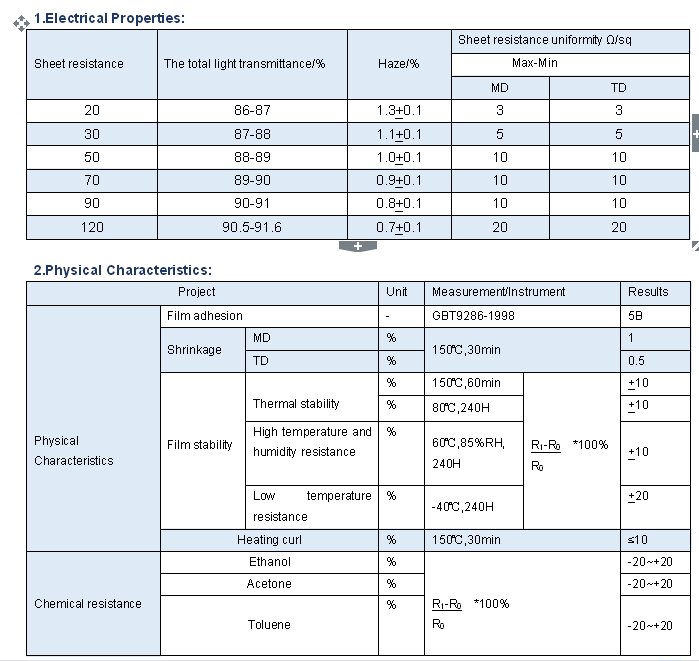

For other transparent conductive material , AgNWs-Film has the following advantages: AgNWs-Film has high light transmittance, good conductivity and stability, soft, simple production process, high finished product rate and low cost. It can realize large area printing and has a wide range of options on substrate materials. For the application of large size devices, it has obvious advantages. (1)Compared with metal mesh, Murray interference problem does not exist on AgNWs-Film. It can be applied to various sizes of display screens and has a higher light transmittance and a smaller bending radius. The transmittance can reach 90% when sheet resistance of AgNWs-Film at 30-50ohm and resisstivity largely unchanged after repeated bending. (2)Compared with ITO-Film, AgNWs-Film has the following advantages: *ITO belongs to brittle material, it does not apply to the flexible touch screens and the cost has been stubbornly high. AgNWs-Film has better flexural endurance and lower cost. *The phenomenon of the plunge of transmittance and the dramatic increase of haze on ITO-Film will occur with the reduction of sheet resistance and the increase of the thickness of conductive layer. AgNWs-Film does not have this problem. *Take GF for example, ITO sensor line needs to be bound and printed silver pulp because of its high electrical resistance, while silver nanowires sensor line with low resistance can bind directly,which simplifies the process and save the cost. *ITO-Film is difficult to realize double coating, high-end products need to adopt GFF structure, so it possesses poor optical performance and low finished product rate, while AgNWs-Film can achieve double-sided conduction, which possesses good optical performance and high finished product rate. (3)Other advantages: The AgNWs-Film uses silver nanowires dispersion gum and protection gum, which are all inorganic materials.It also has the advantages as follows: •1,Low resistance and haze, high transmittance. Transmittance>88% and haze<1.2% when sheet resistance at 30-50ohm/sq. •2,Strong adhesion, Using 1kg force to wipe with a clean cloth after taking alcohol the resistance has not been changed after 100times. •3,Stable performance.It will not appear the phenomenon of yellow or silver wire migration after a long time. •4,The line width can be done at 35um or less, normal resistance, no swell occurs. •5,Either laser technology or Yellow light technology can also be used. •6,There is no matching problem with silver paste.Silver paste of high or low temperature all can be used. •7,TP with small or medium size do not have to print silver paste. •8,Good performance of anti-bending, suitable for touch screens of high and low curvature.

| *Temperature and wet resistance:AgNWs-Film was baked at 120c for 30 minutes. *Chemical resistance:AgNWs-Film was soaked in solvents for 10min at 25c or wiped with 1kg force using a wet cloth with organic solvent. |

Related Keywords

Related Keywords

You May Also Like

You May Also Like